A case study of the product development process for industrial design at SharkNinja, through the Shark HydroSweep project in 2023

HydroSweep Concept Evolution

A snapshot of the ID concept as it evolved through months of design and development.

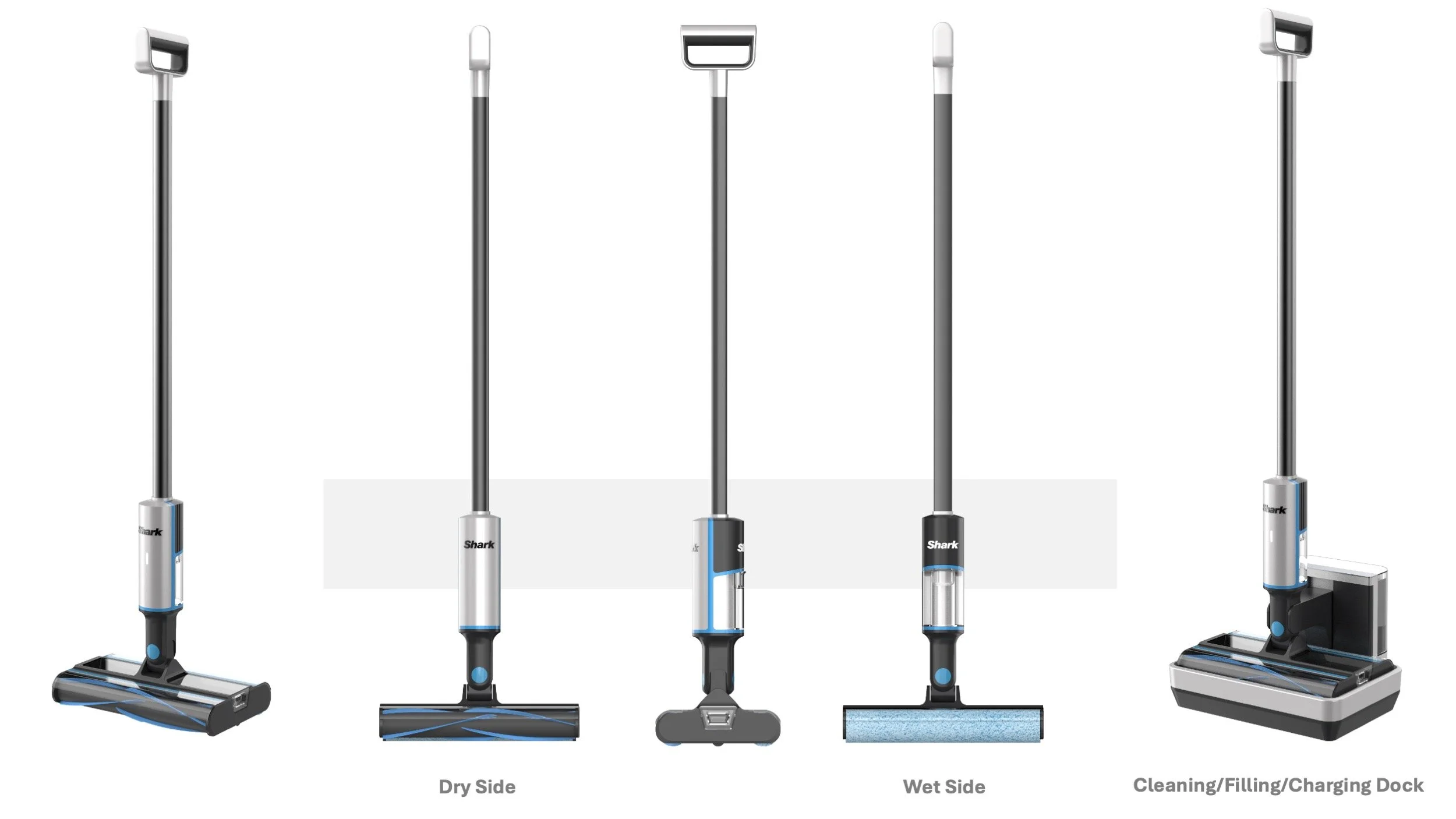

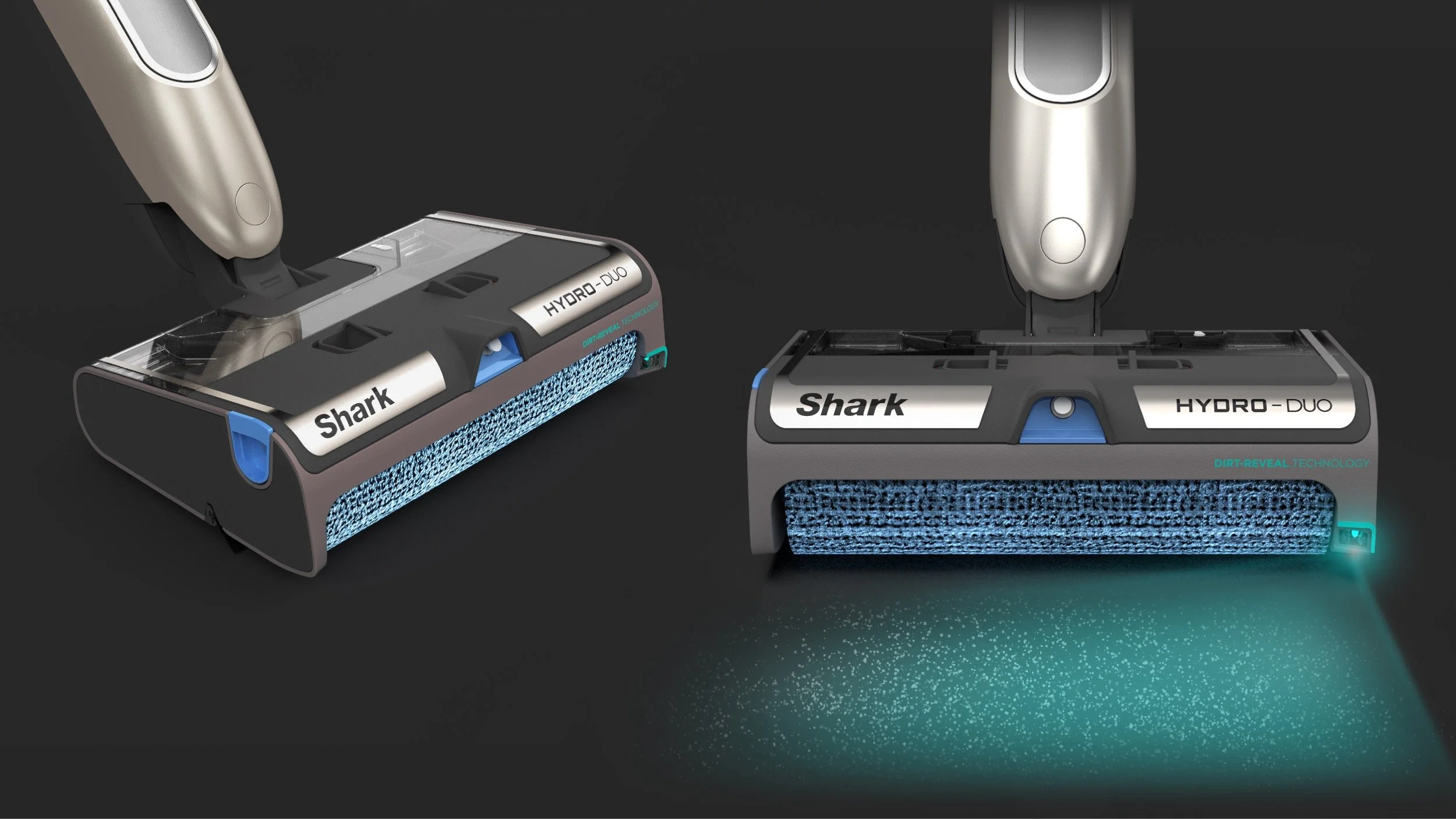

“Hack-Week” ID Concept Visualization

Though a week long hack with cross-functional teams, we generated a product proposal to leadership for our first ever combination wet & dry sweeper with no suction motor. ID developed “sizzle” visuals aimed to garner excitement and believability around the concept. Shortly after review, the program was green-lit and product development commenced.

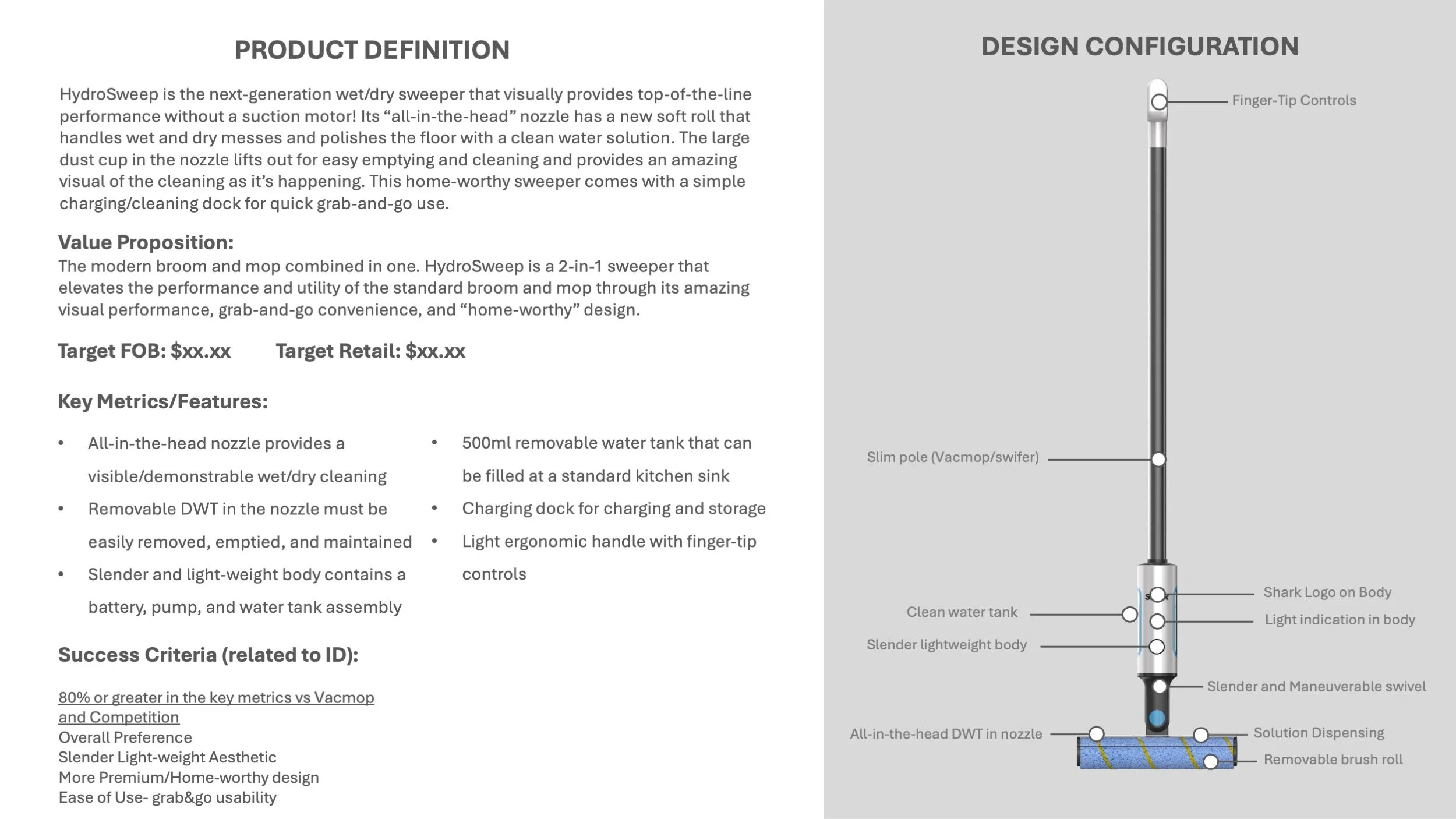

HydroSweep - Product Brief Overview

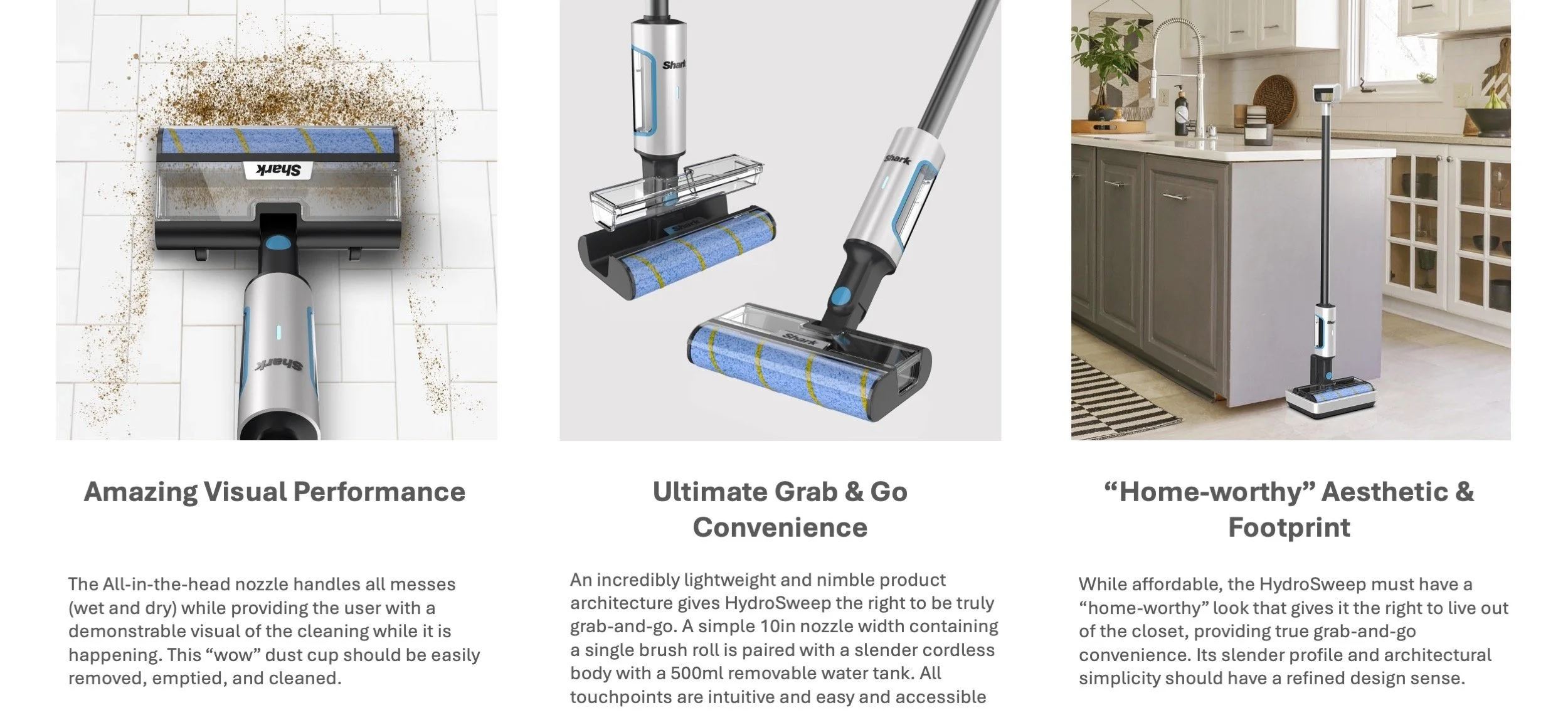

HydroSweep - Product Design Pillars

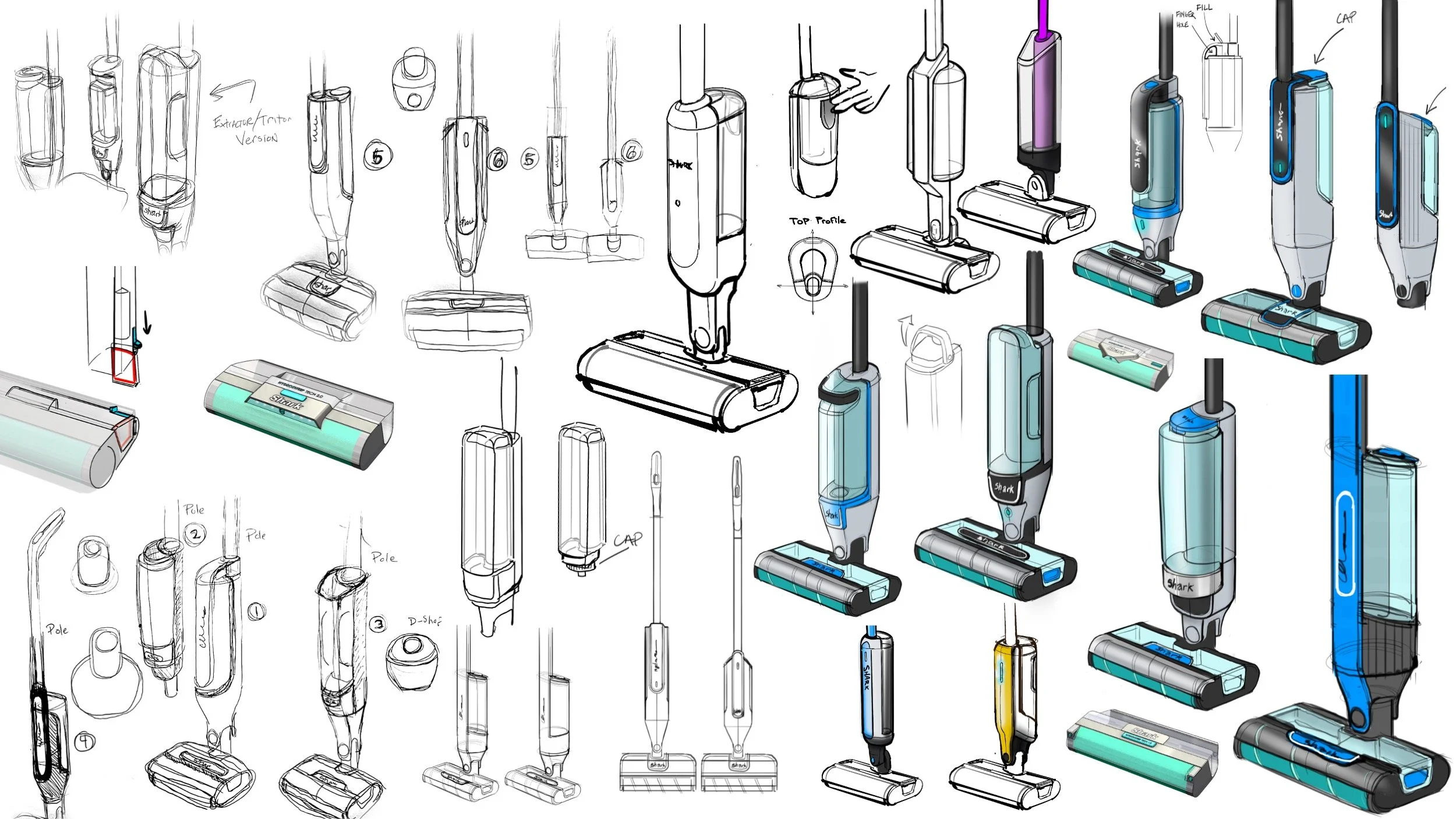

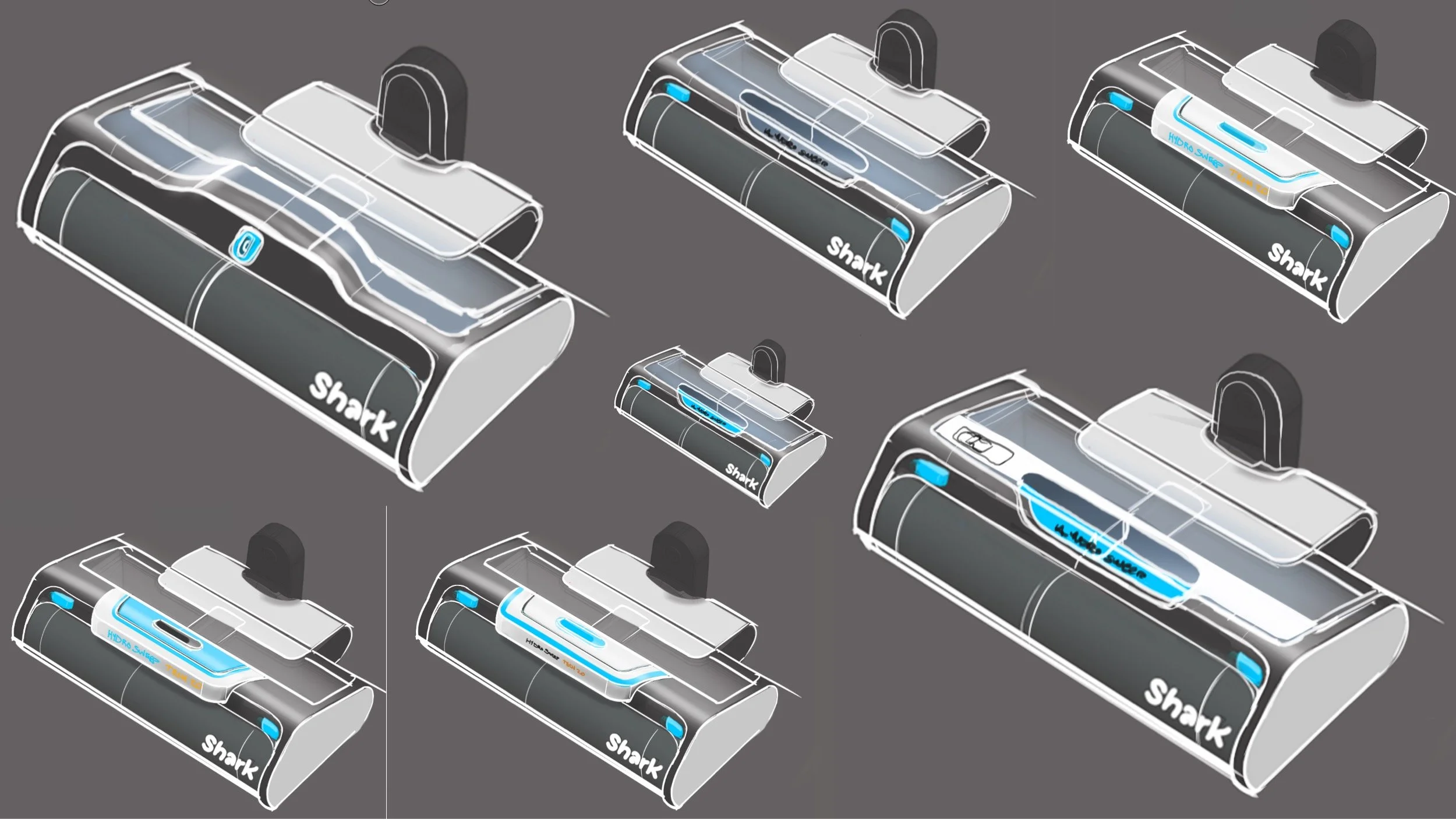

HydroSweep - P0 ID: Initial Sketch Concept Exploration

With aligned design pillars and product functionality, ID commenced explorative concept sketching, based on a loose engineering schematic, to visualize form language and design identity opportunities.

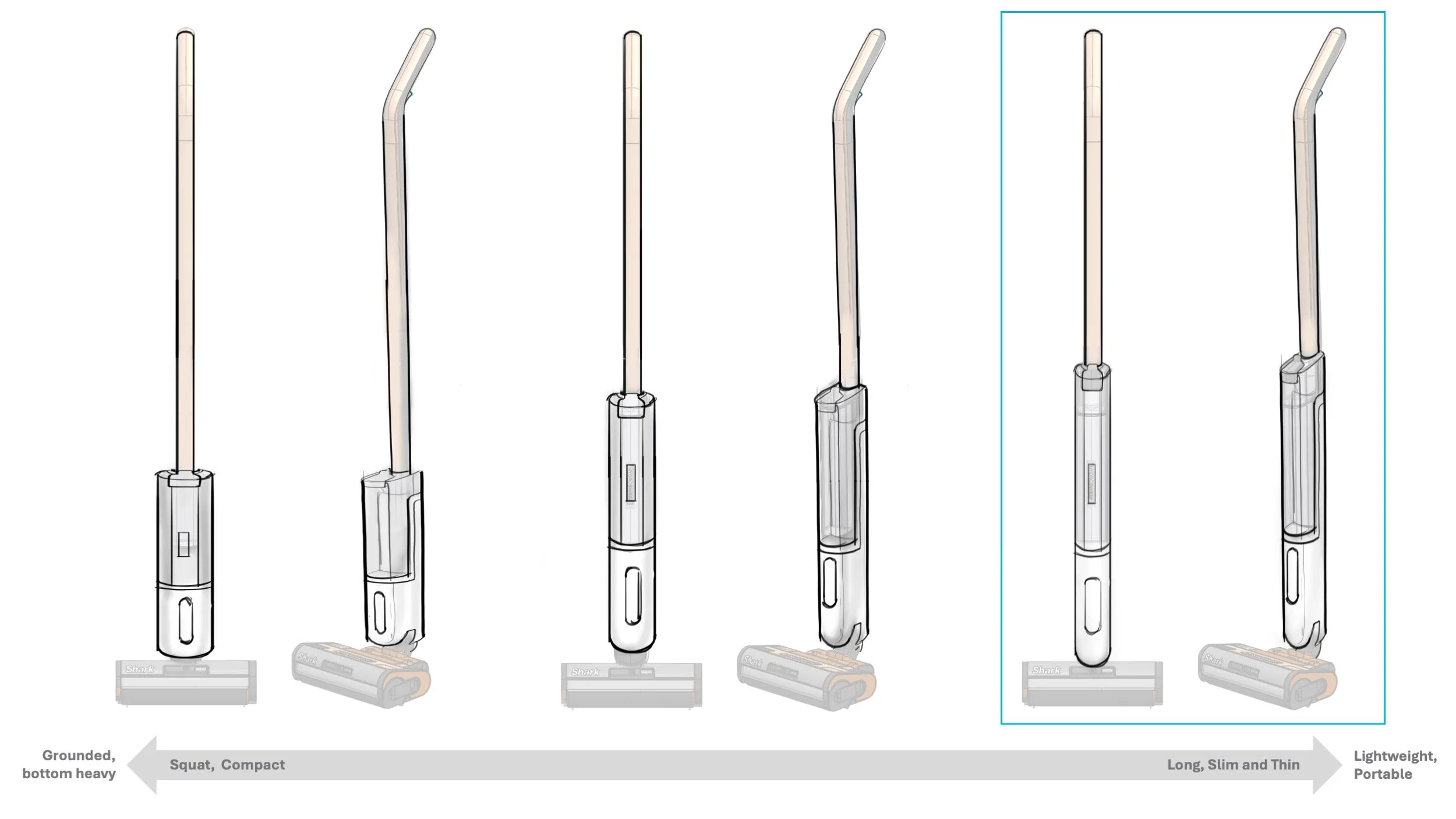

HydroSweep - P0 ID: Initial Concepts Lineup

Initial ID concepts were reviewed with the cross-functional teams with aligned concepts to chase for further refinement.

HydroSweep - P0 ID: Design Concept Identity “Buckets”

The ID team dissected the feedback and developed visual “buckets” that communicate the key attributes for each concept.

HydroSweep - P0 ID: Concept “Pierce”

HydroSweep - P0 ID: Concept “Intersect”

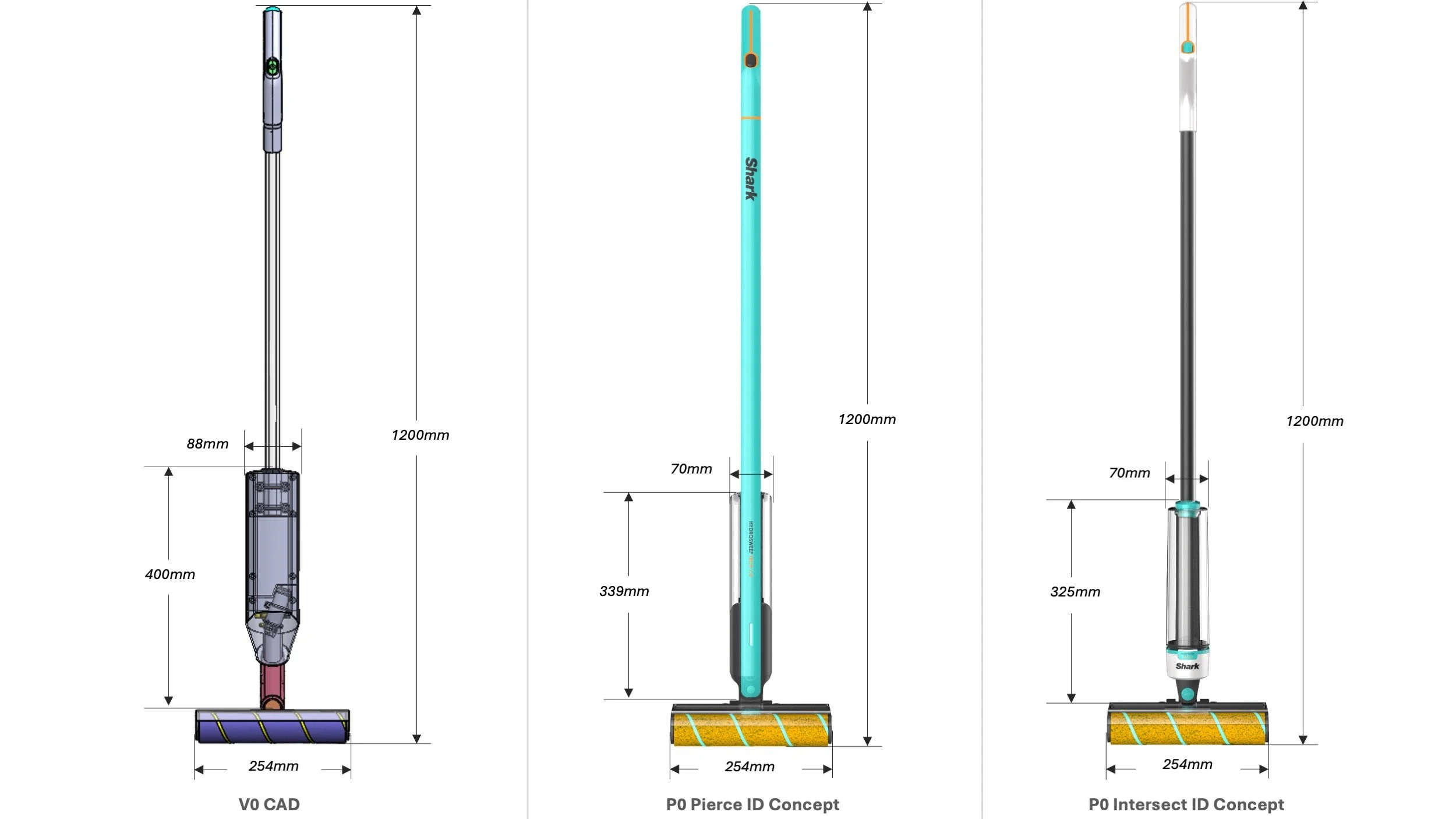

HydroSweep - P0 ID: Concept Comparison

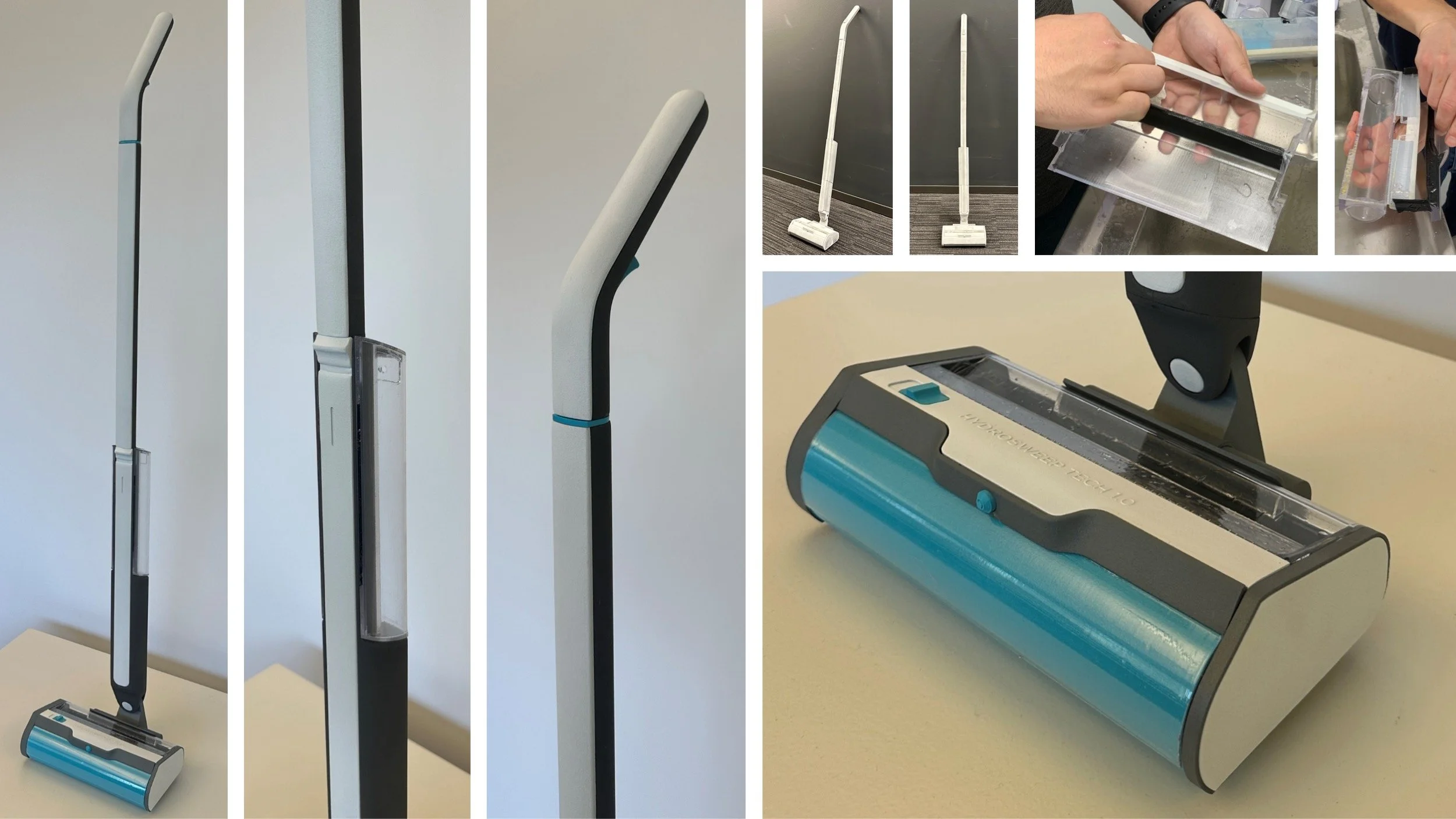

HydroSweep - P0 ID: “Pierce” Volume Model Studies

Upon review of the concept refinements, the team aligned to proceed with concept “Pierce” for the P0 design. Physical to-scale models were made to evaluate the size and proportion of the design.

HydroSweep - P0 ID: Concept Refinement

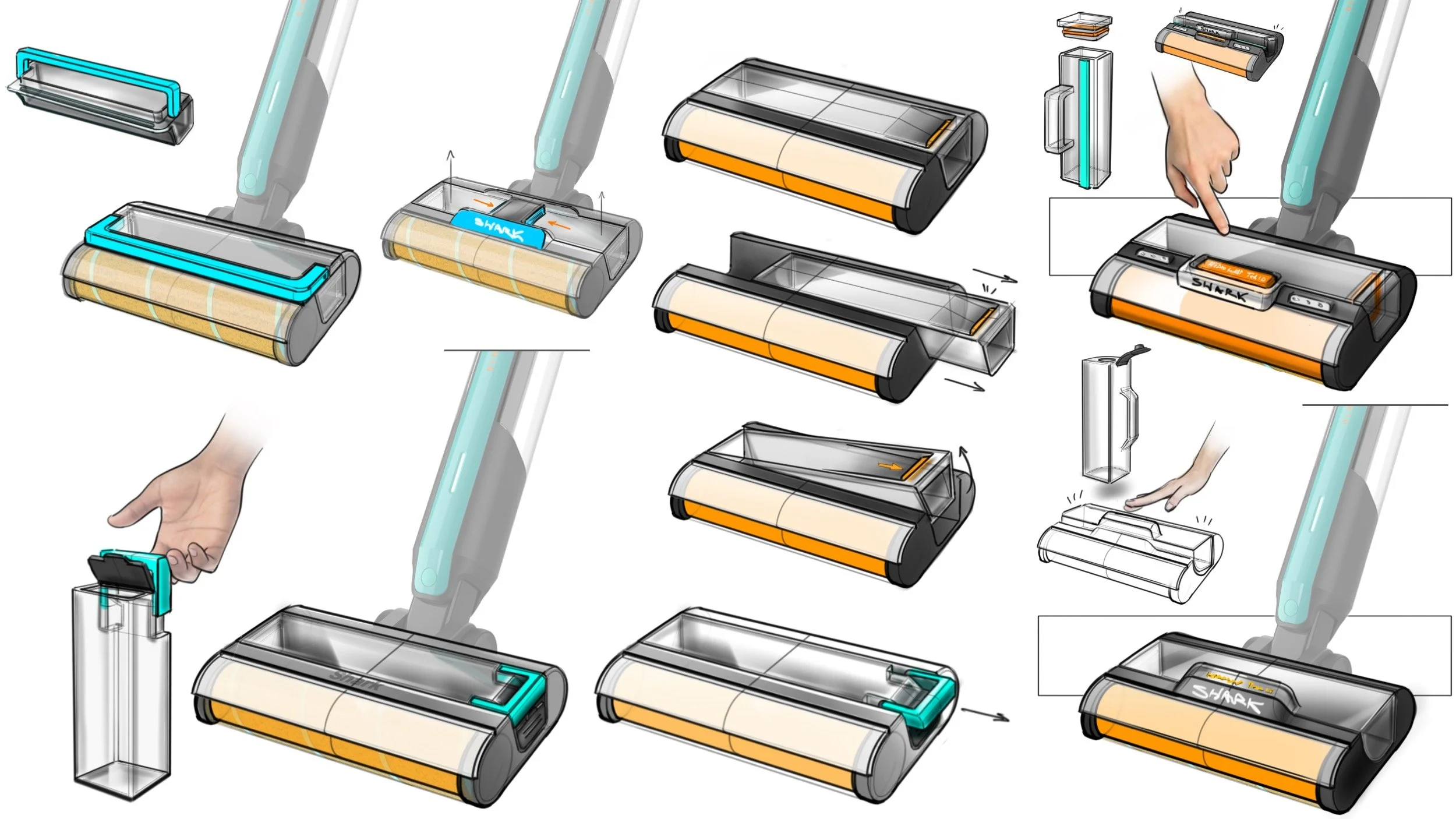

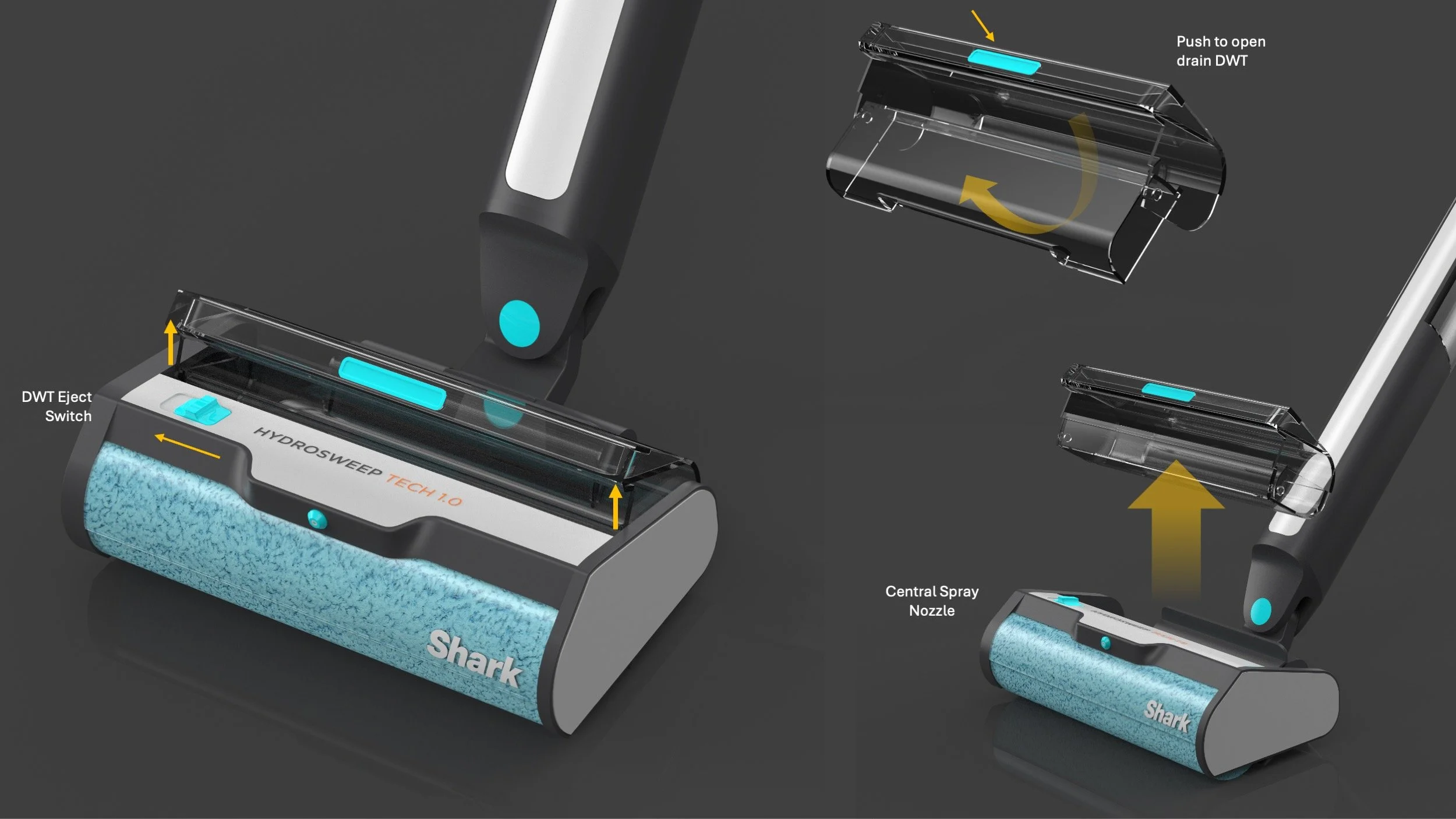

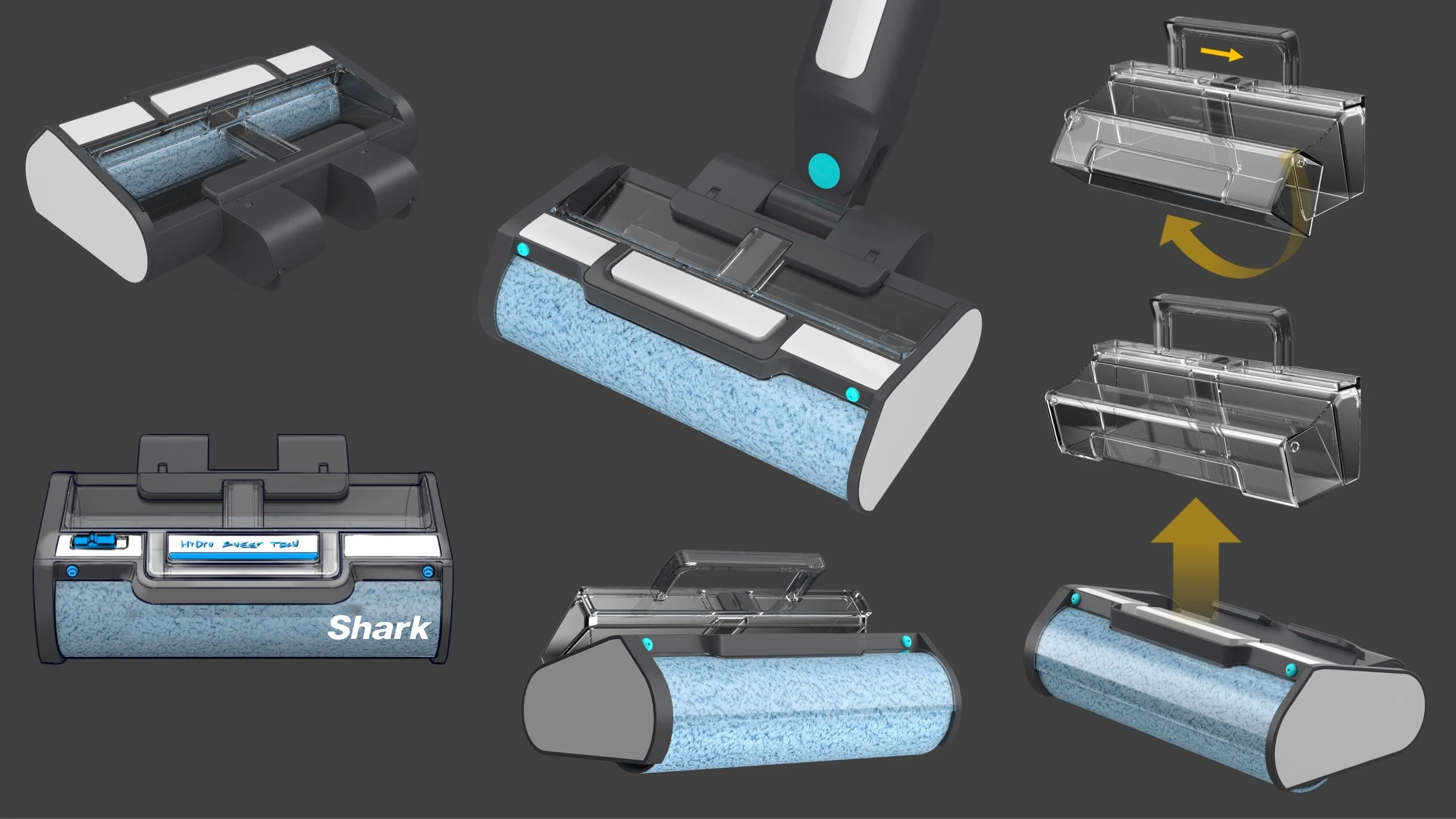

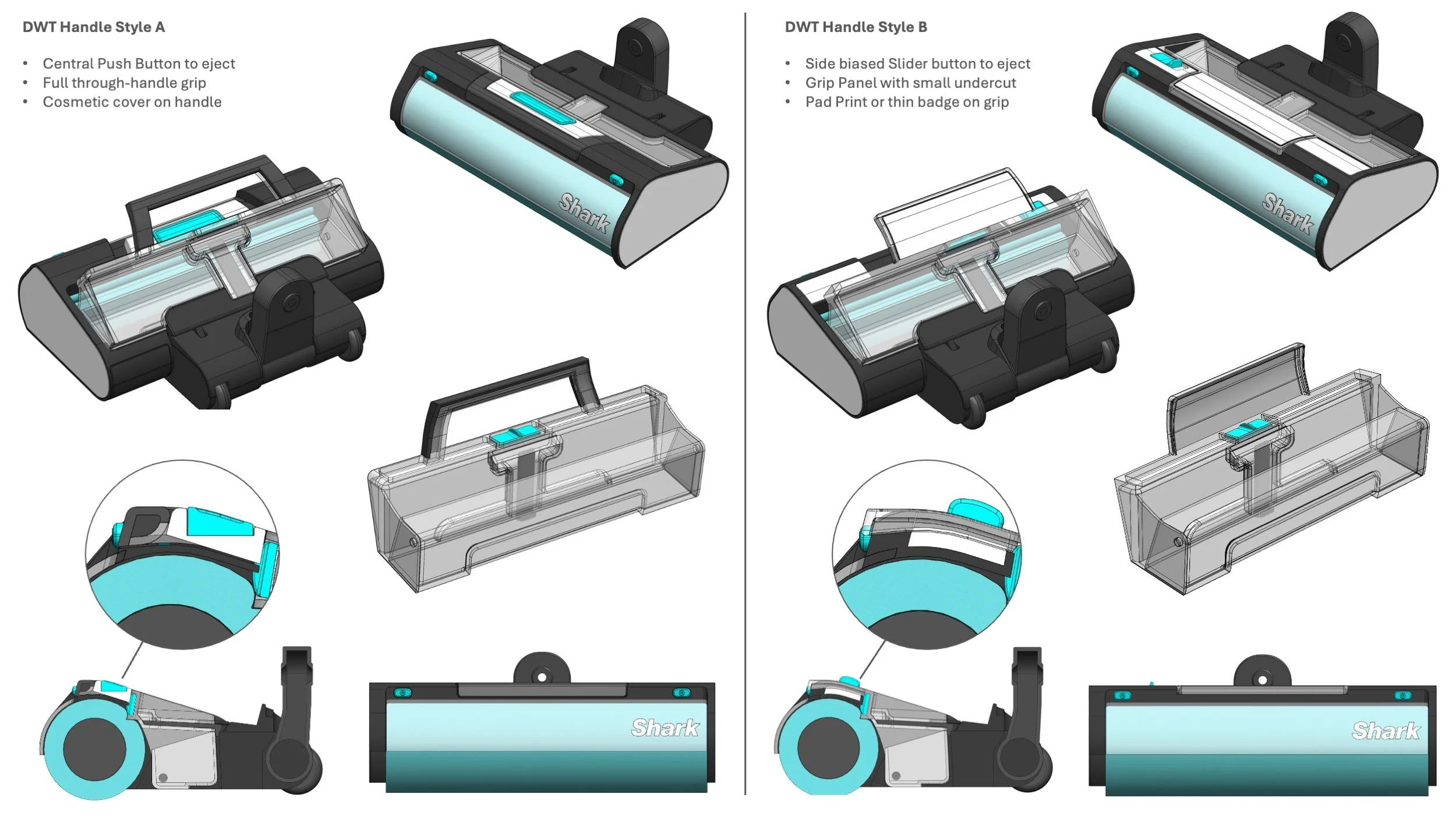

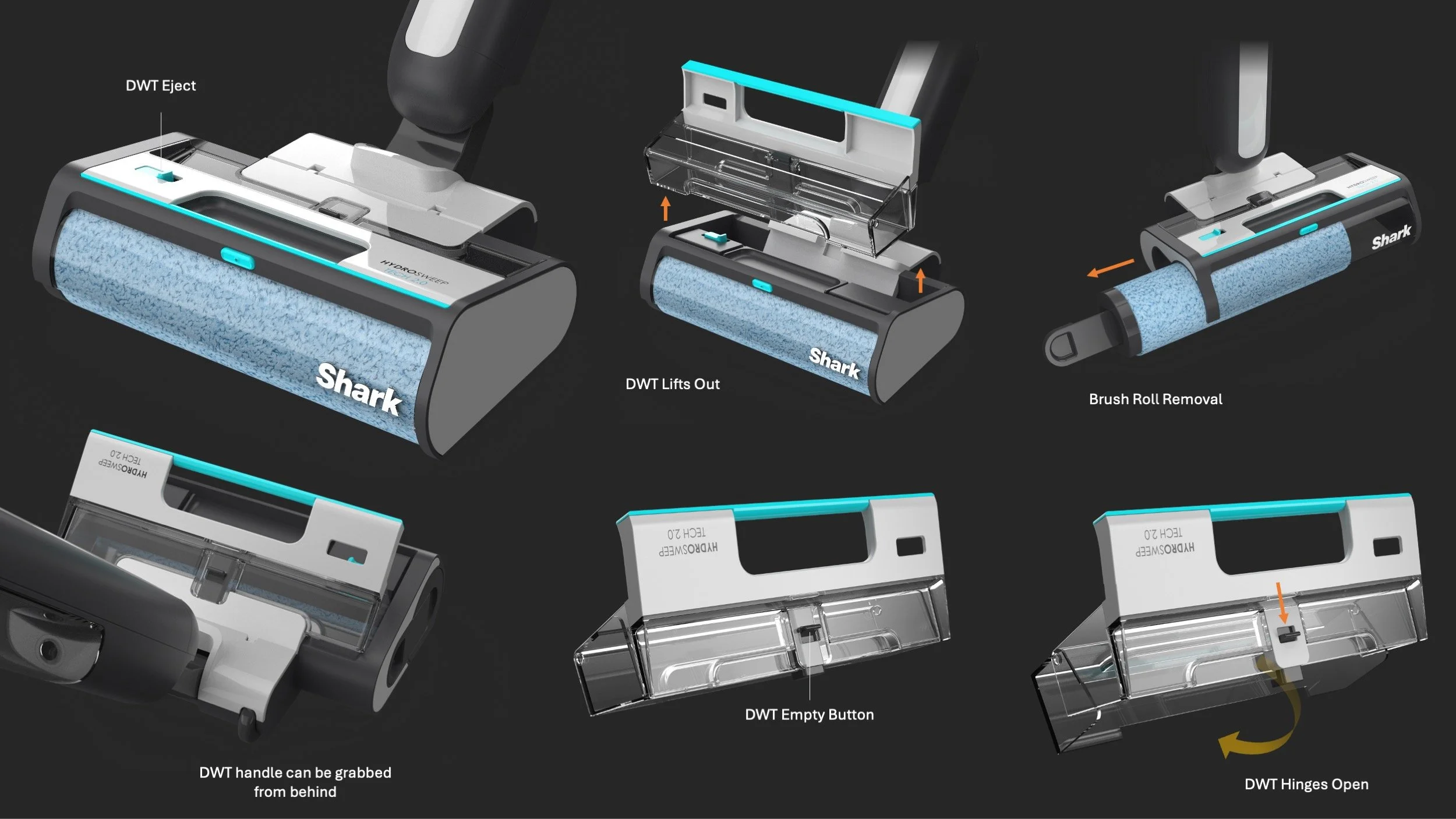

HydroSweep - P1 ID: Nozzle UX Exploration

The bulk of P1 design development surrounded the nozzle engineering performance and user experience. The team had to really dig in and refine how the brush roll and dirty water tank system worked together and how that impacted the user journey. It was paramount to provide amazing cleaning while also providing a clear and simple experience for the user to interact with, use, and maintain.

HydroSweep - P1 ID: Refined Nozzle Concept

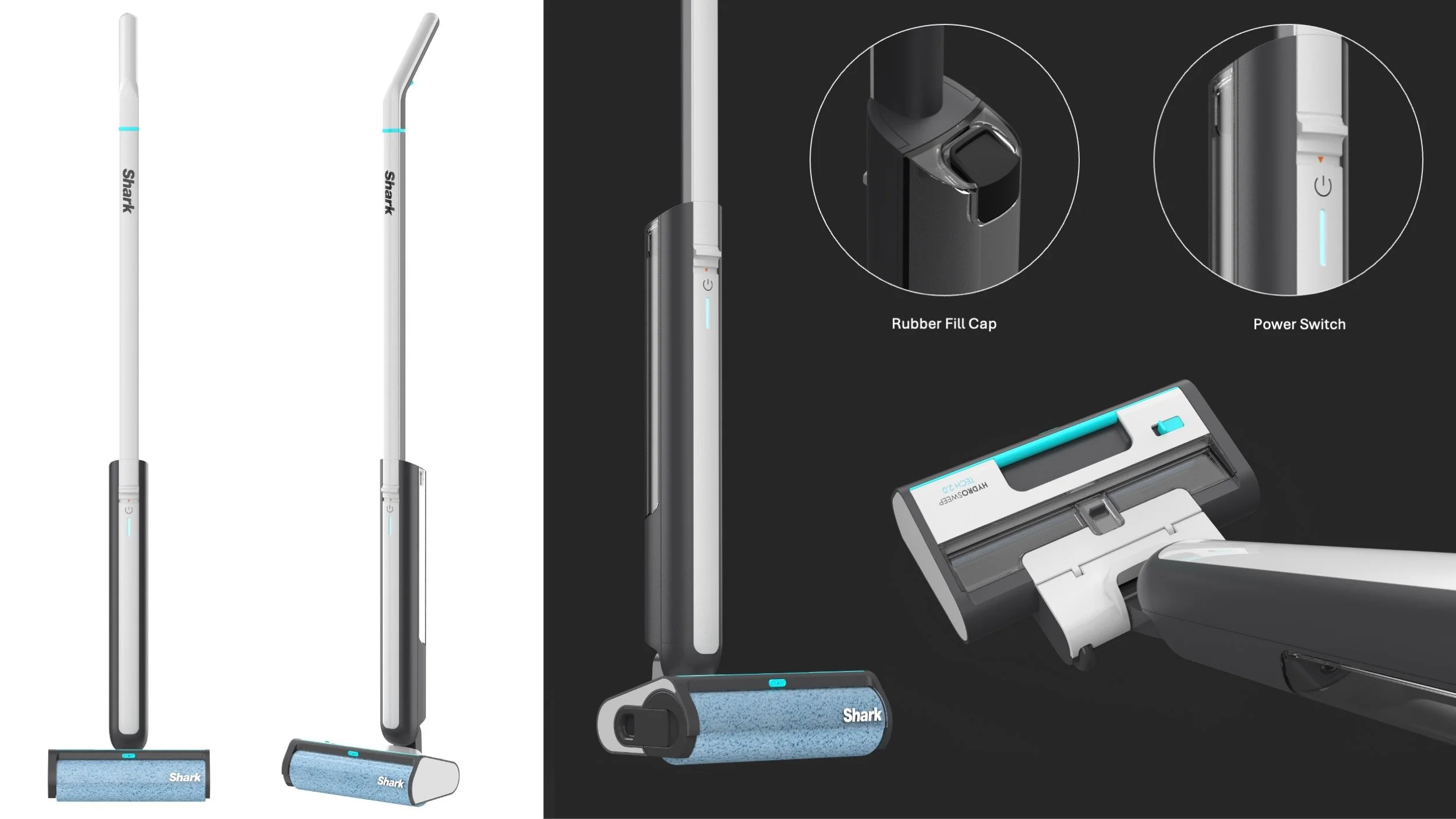

HydroSweep - P1 ID: Concept Refinement Overview

HydroSweep - P2 ID: Architectural Pivot

In reviewing the P1 design, it was deemed that the “Pierce" concept looked too much like a cordless sweeper and did not celebrate the duality of wet mopping effectively. We kicked off a “design accelerator” to explore new concepts that would celebrate the wet & dry cleaning. In starting this exploration, we first did a gut check to ensure that our architectural approach was the appropriate proportion for the design. The team aligned to proceed the tall & slender archetype with the clean water tank on the front.

HydroSweep - P2 ID: “Accelerator” Concepts

The concepts were reviewed with the cross-functional team and the preferred options were put into online consumer insights testing. The winning concept was Concept A (pictured center below)

HydroSweep - P2 ID: Primary Path Concept

HydroSweep - P2 ID: Concept Refinement

ID was tasked to lean further into the playful fluid mopping nature of the product. We looked to introduce more softness and symmetry to the body to embellish this.

HydroSweep - P2 ID: Concept Comparison

HydroSweep - P2 ID: Design Overview

HydroSweep - P2 ID: Body Refinement

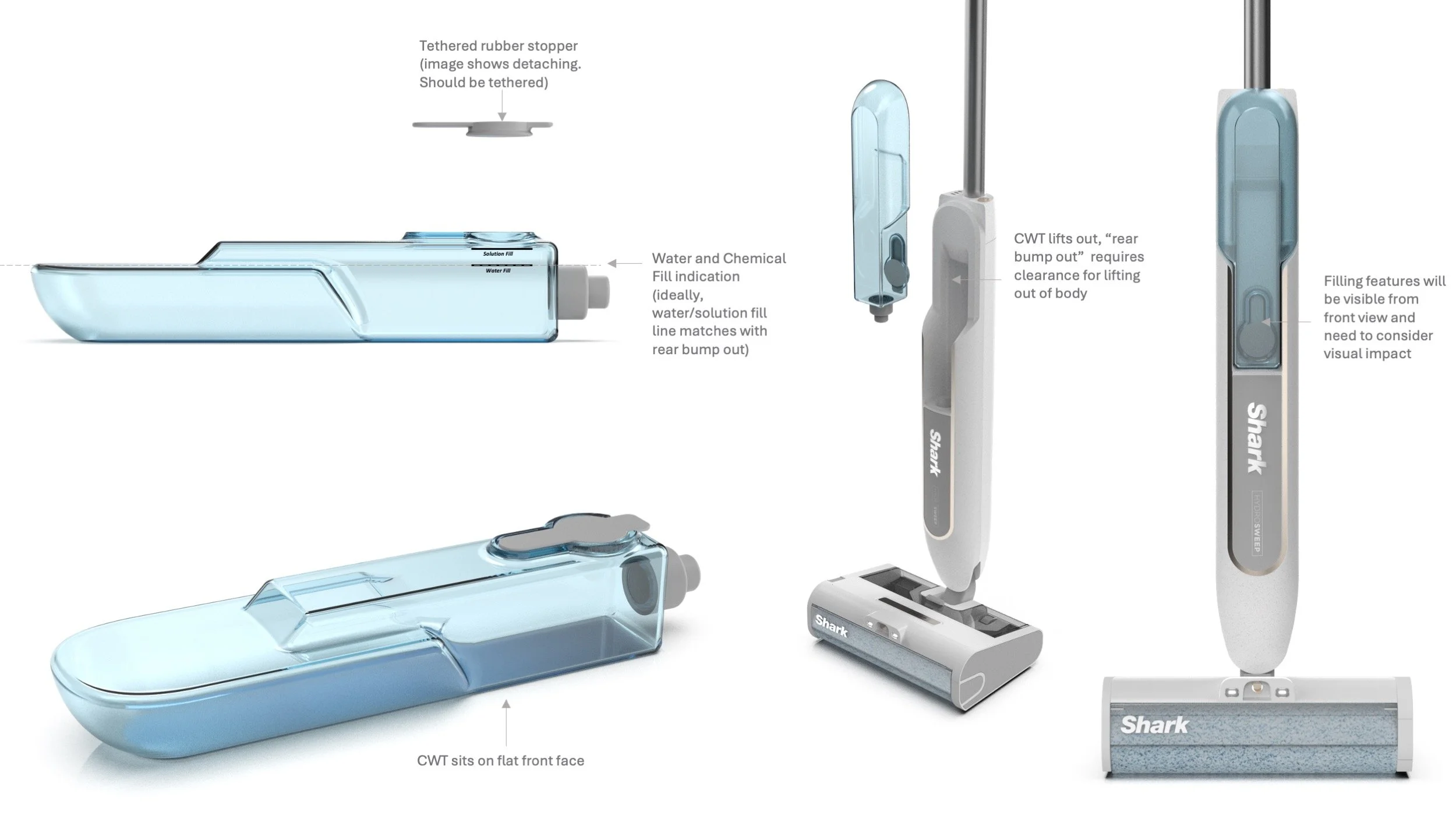

HydroSweep - P2 ID: Clean Water Tank Detail

HydroSweep - P3 ID: Clean Water Tank Conundrum

The P2 ID regarding the clean water tank became a big issue upon review of the P2 samples. The round top water tank ID was heavily preferred aesthetically, but was much less user friendly from a UX standpoint. Due to the nature of requireing a measured mixture of both clean water and cleaning solution, the horizontal style filling was much more difficult and not nearly as grab-and-go compared to the flat top design. The team did extensive investigation around the design through visualizations and prototypes to reach an aligned direction.

FLAT TOP vs. ROUND TOP

HydroSweep - P3 ID: Concept Evolution

After many discussions and reviews, the team aligned that it was most important to maintain a premiere user experience and pivoted to the flat top clean water tank design for the P3 build.

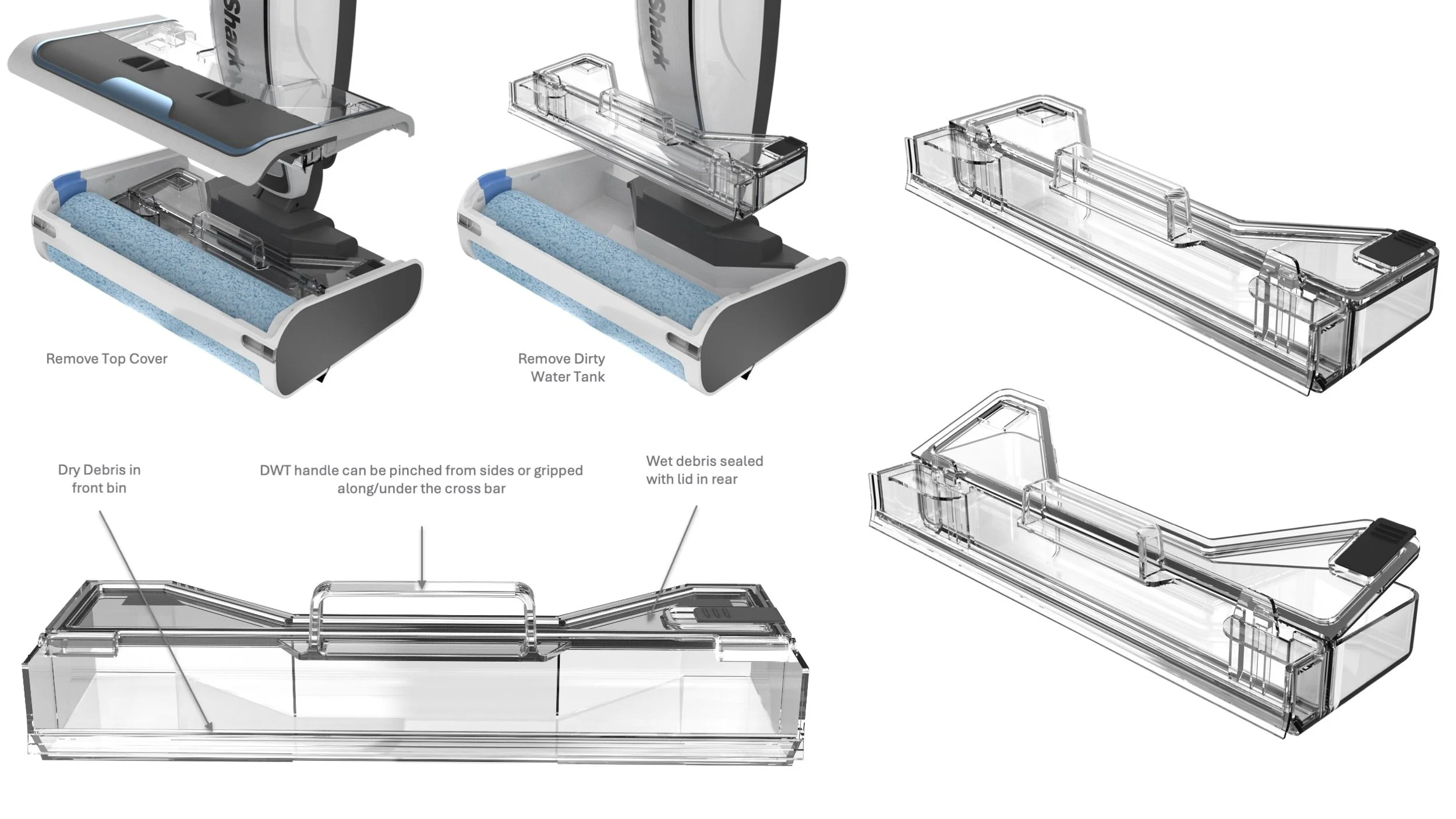

HydroSweep - P3 ID: Nozzle UX Refinement

Nozzle UX was further refined to a simplified construction with a removable top cover and dirty water tank housed within. You’ll notice the contextual renders depict another cleaning product that was being developed in tandem using the same “all in the nozzle” platform.

HydroSweep - P3 ID: CMF Concept Colors

ID and CMF worked together to develop CMF palettes and blocking that would help keep the “playful fluid mopping” tones even with the return to the flat top clean water tank design.

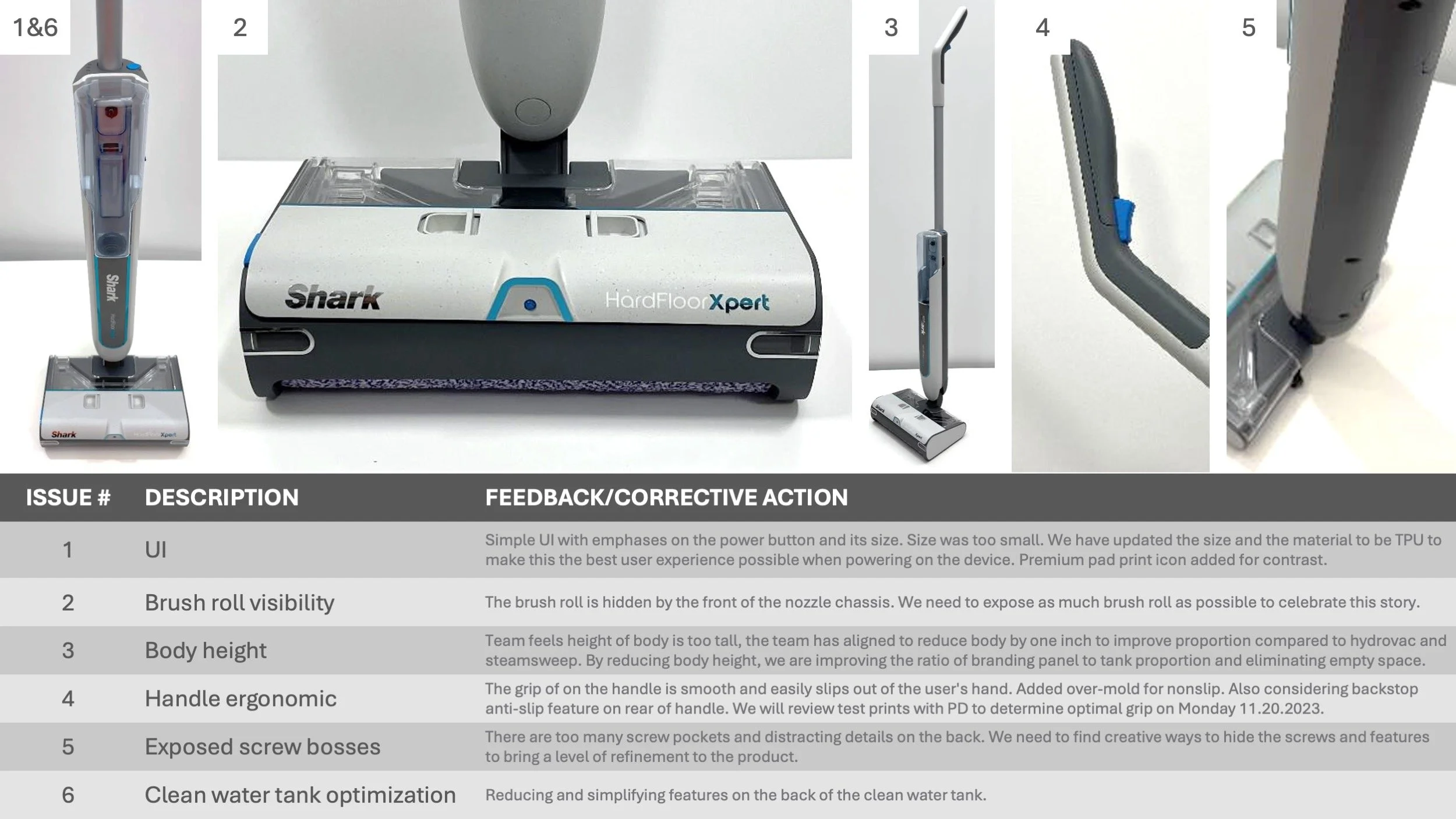

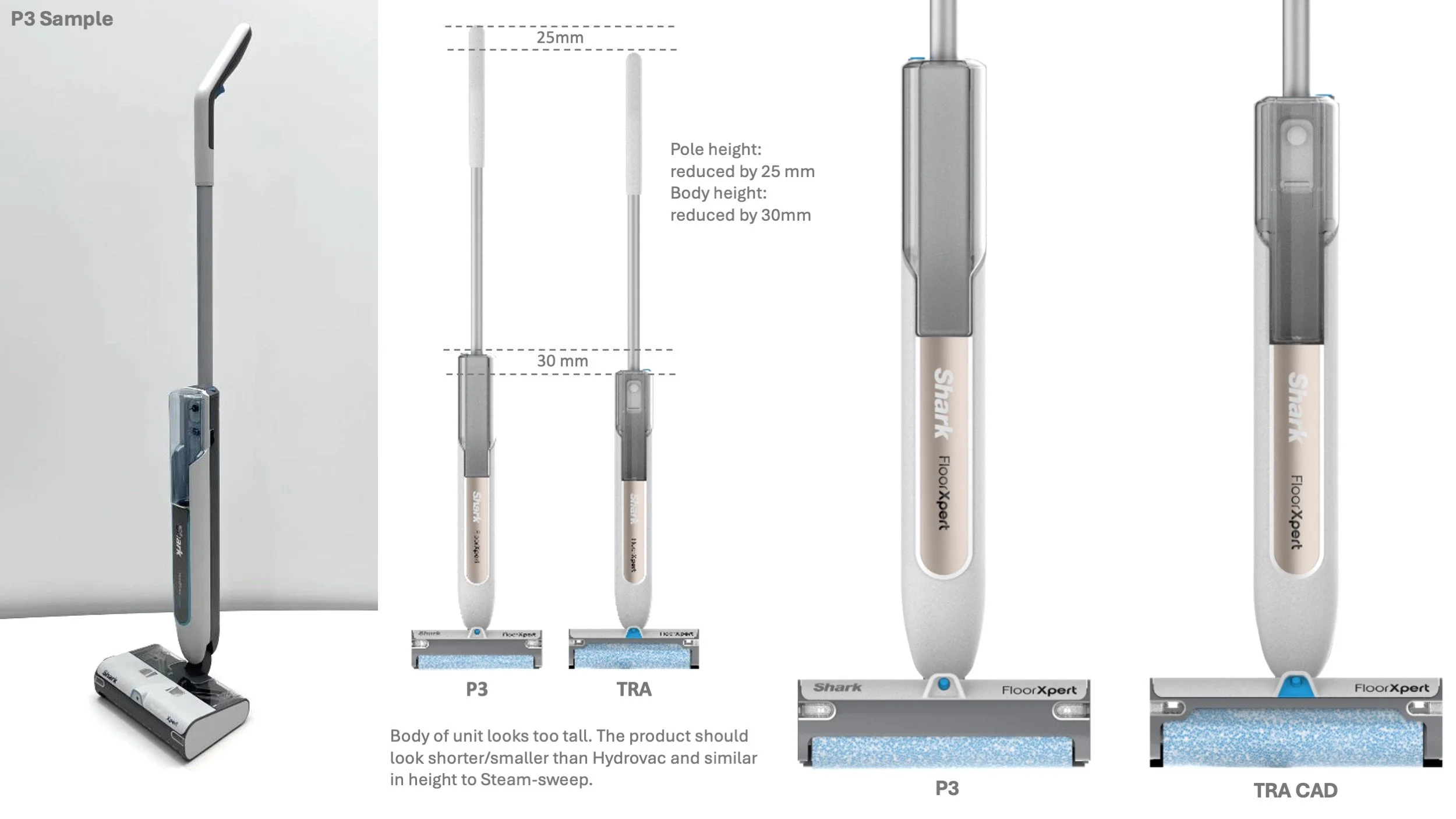

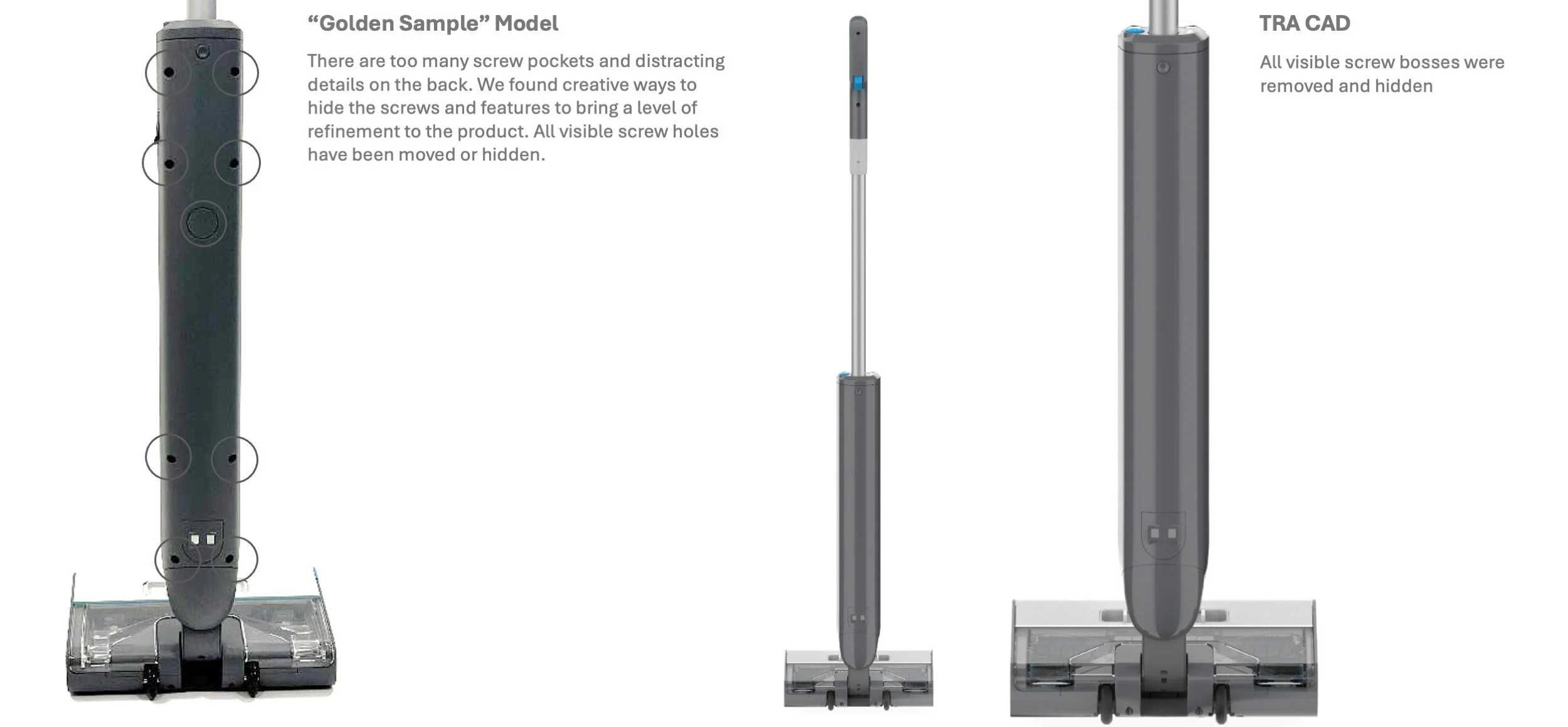

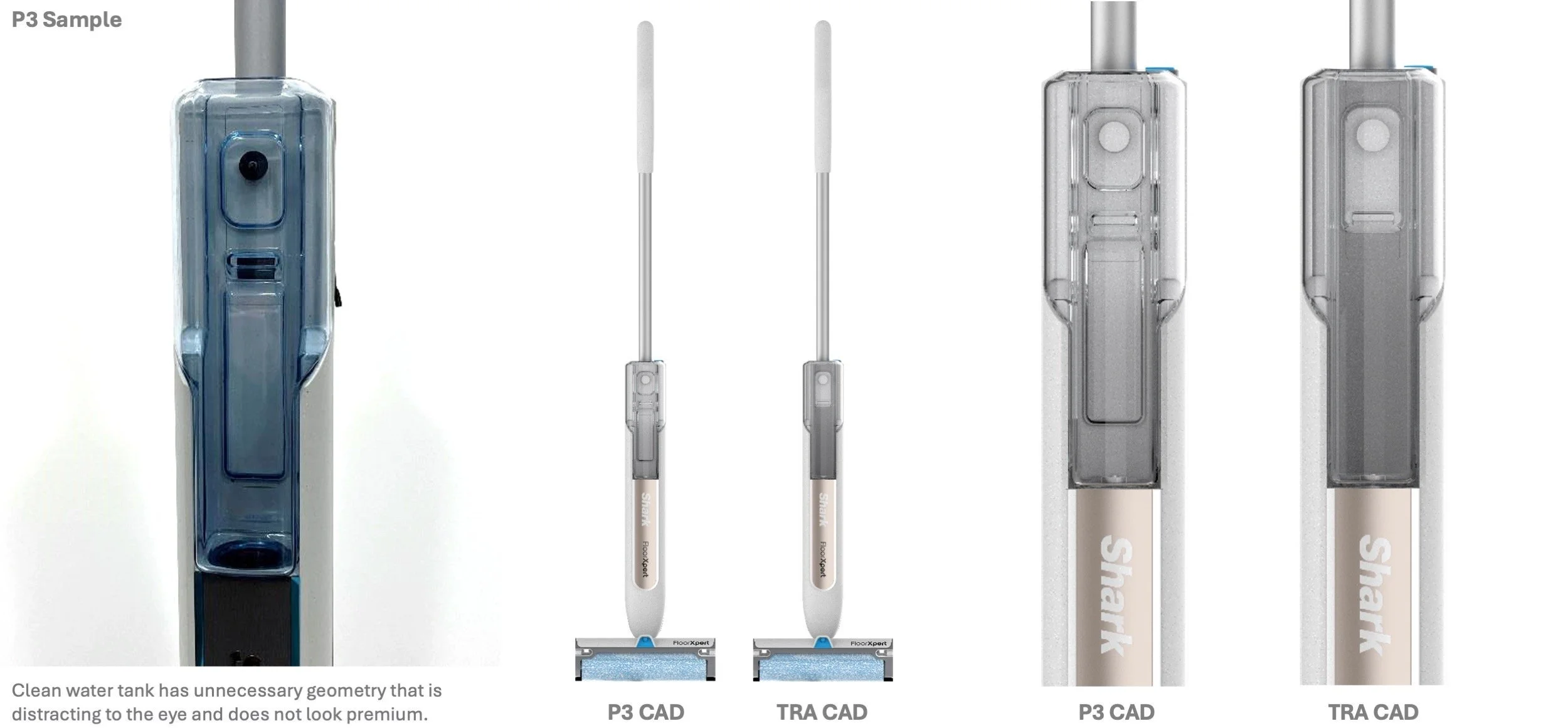

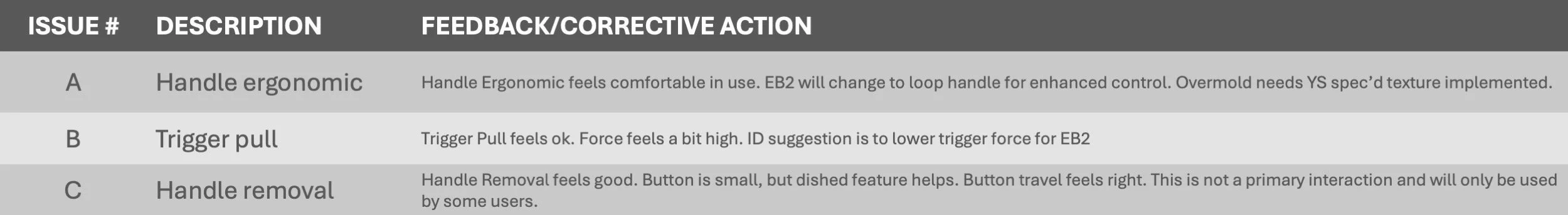

HydroSweep - TRA ID: Design Refinement “Deep-Dive”

With P3 being the final build ahead of steel cut, we commissioned a TRA ID “golden sample” appearance model. Through a meticulous “deep-dive” process in reviewing P3 samples and the ID “golden sample” appearance model, the team identified key areas that needed further refinement ahead of TRA.

HydroSweep - TRA ID: UI Refinement

HydroSweep - TRA ID: Brush Roll Visibility

HydroSweep - TRA ID: Body Height Reduction

HydroSweep - TRA ID: handle Ergonomic

HydroSweep - TRA ID: Exposed Screw Bosses

HydroSweep - TRA ID: Clean Water Tank Optimization

HydroSweep - TRA ID: Refined Concept Overview

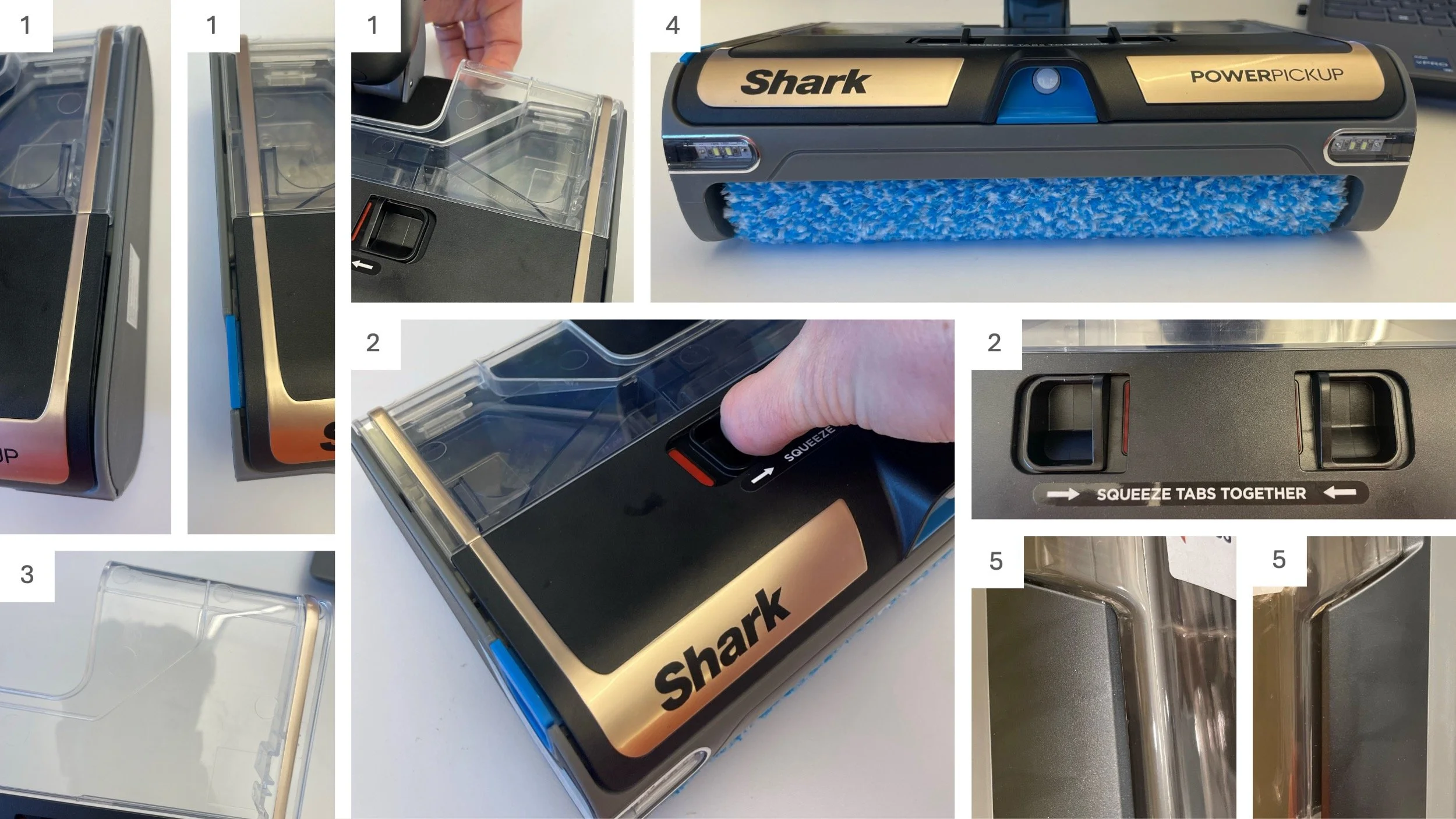

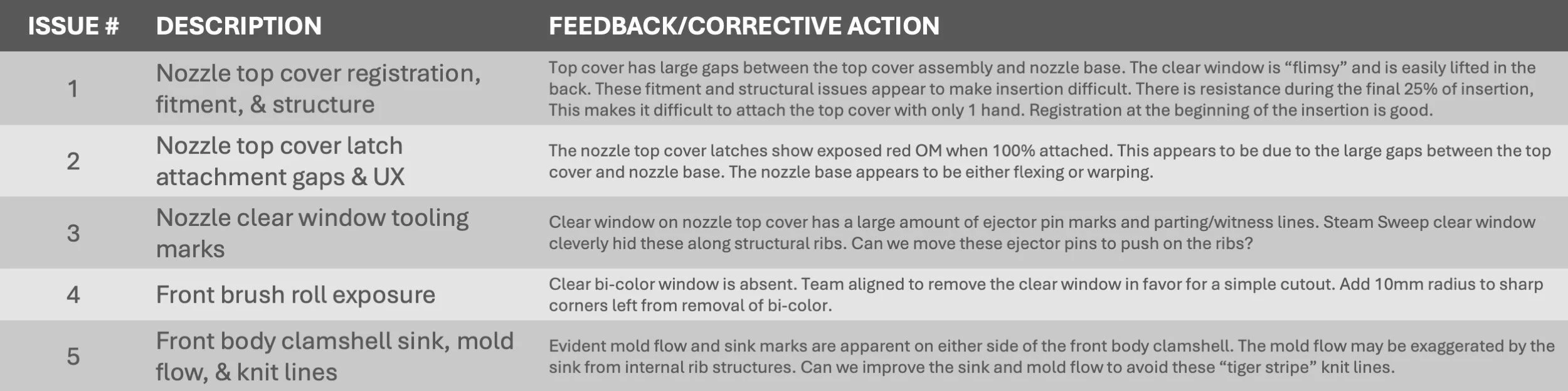

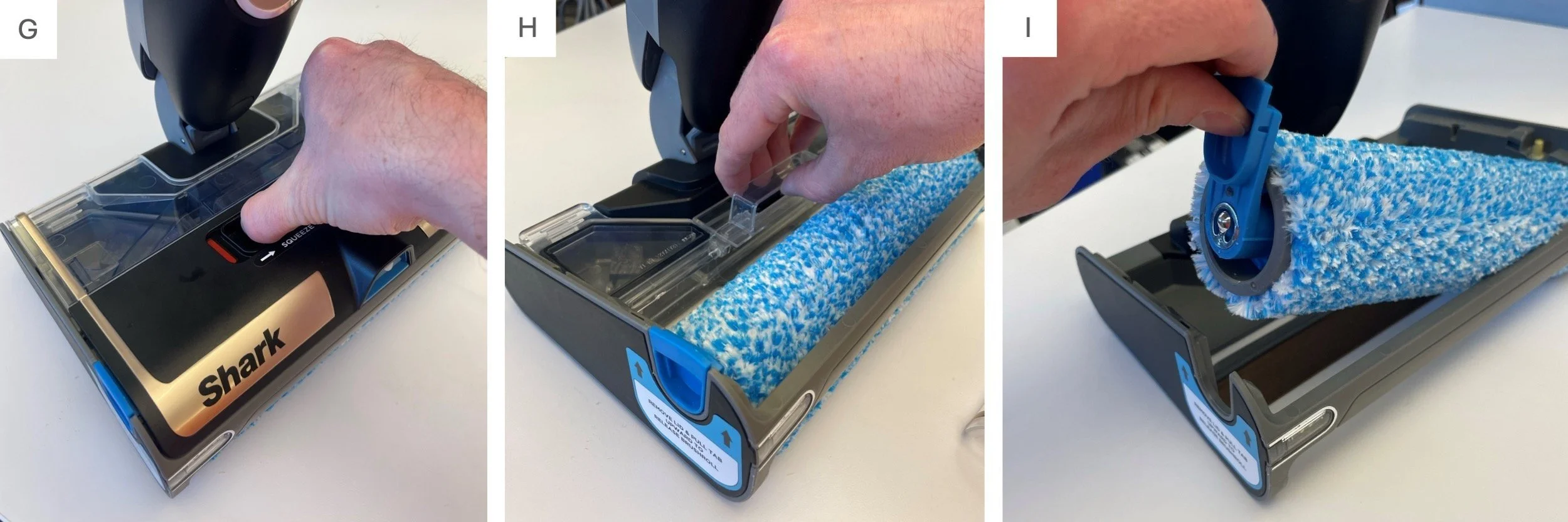

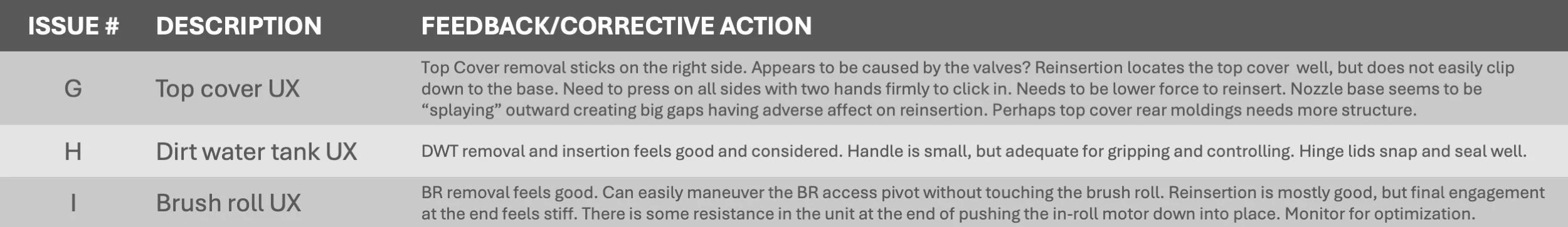

HydroSweep - EB1 ID: Sample Review Deep-Dive

The HydroSweep program had 3 engineering builds (EB0, EB1, EB2). Every sample build underwent vigorous reviews and testing to provide feedback for changes, optimizations, and general improvements. Below is a case study of the EB1 sample “deep dive” showing the review and feedback along with corrective actions.

HydroSweep - EB1 ID: Top Issues

HydroSweep - EB1 ID: Handle UX

HydroSweep - EB1 ID: UI and Clean Water Tank UX

HydroSweep - EB1 ID: Nozzle UX

HydroSweep - EB1 ID: Cleaning UX

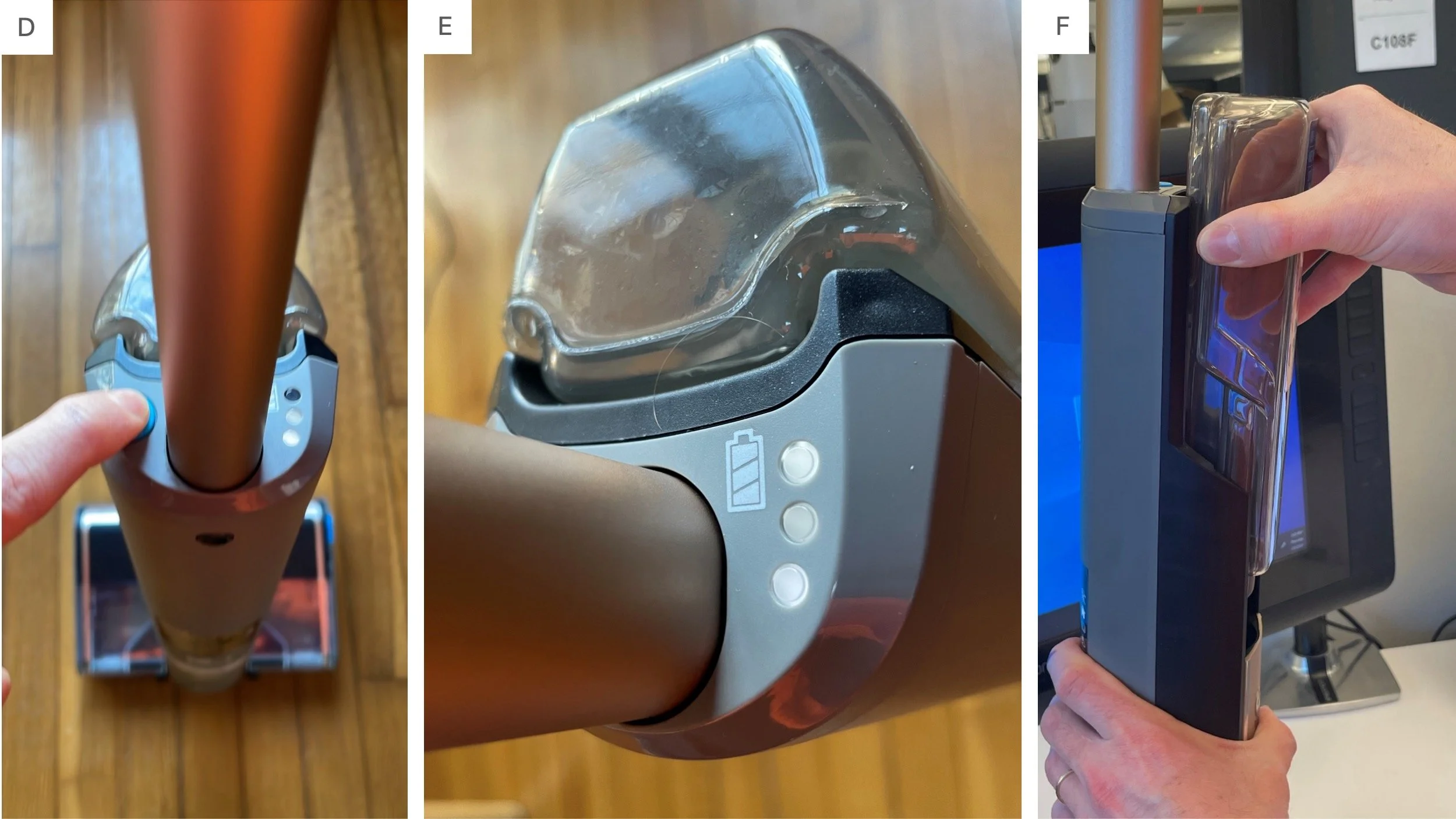

HydroSweep - MP ID: Final Design Overview

The final design for mass production.