A snapshot of the ID development for Shark’s Steam Pickup 3-1, Sharks first steam cleaning solution that picks up debris, mops, and sanitizes.

SteamSweep - ID Evolution Overview

A chronological concept timeline of the design development showing the ID evolution.

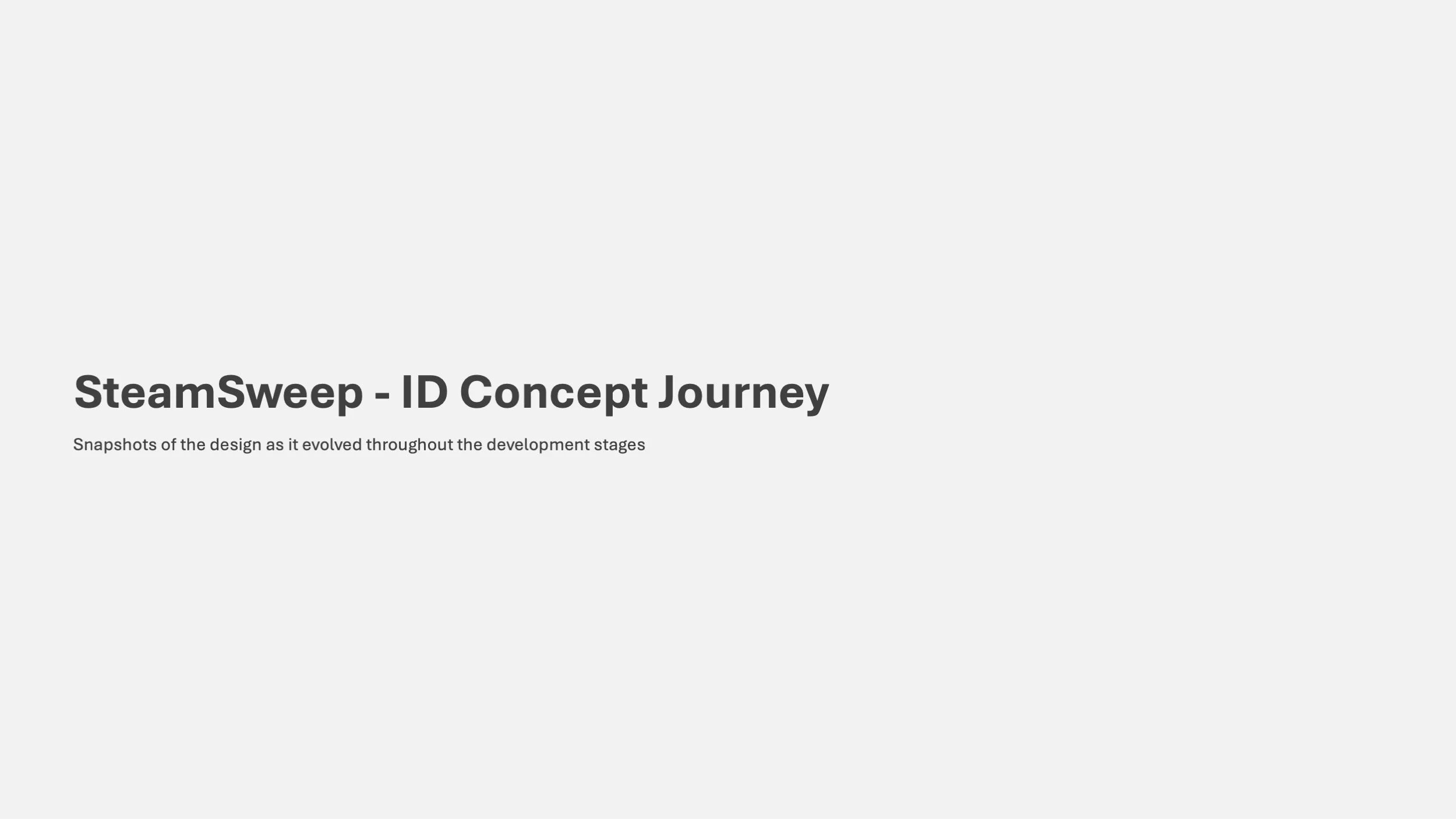

SteamSweep - P0 ID

The first embodiment of the design sought to connect SteamSweep to the existing Shark Steam Scrubber family design language.

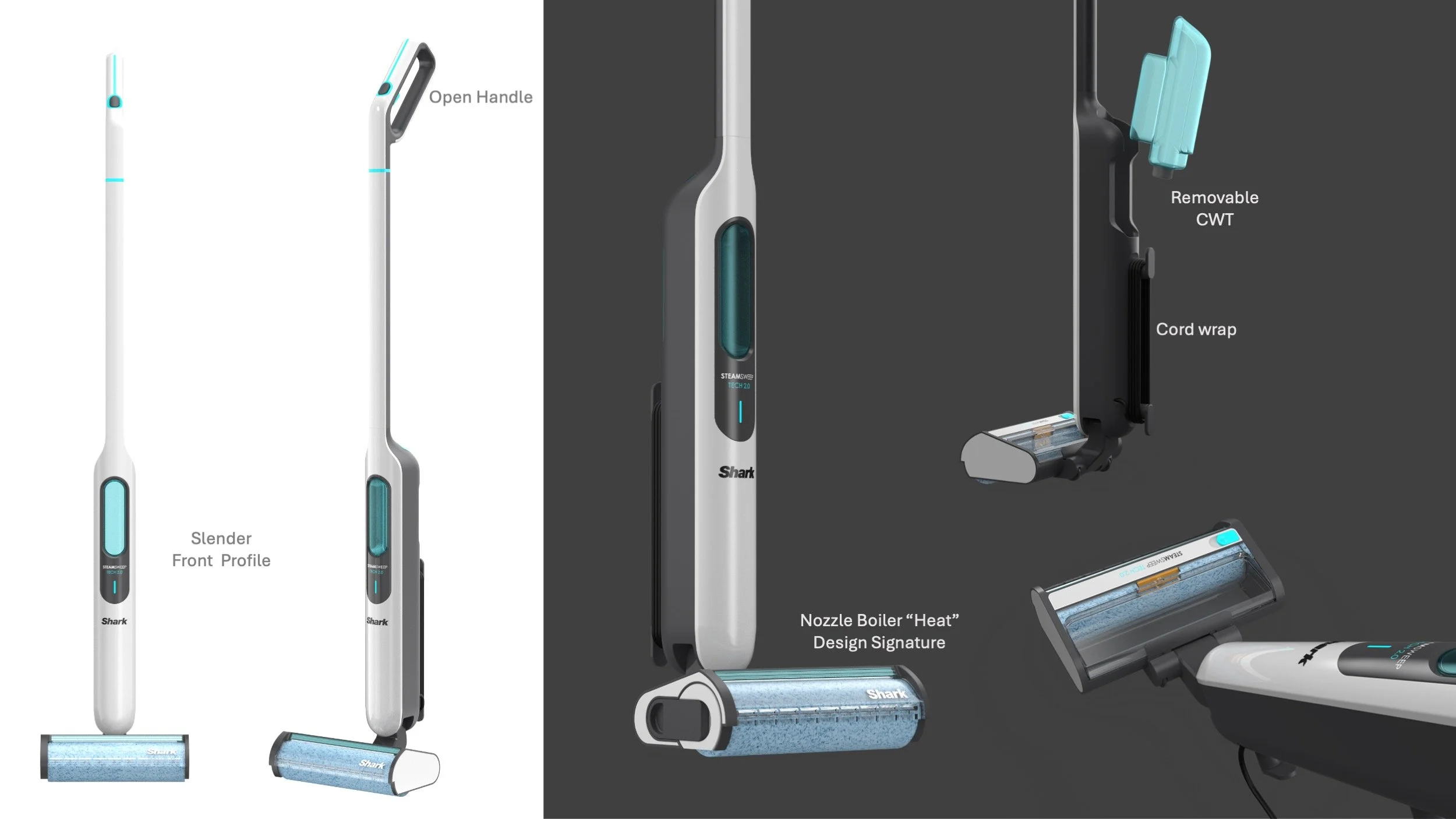

SteamSweep - P1 ID

During P1, the team pivoted the design to differentiate from the scrubber family, and sought to establish an new cohesive design language for the new “Sweep” offerings.

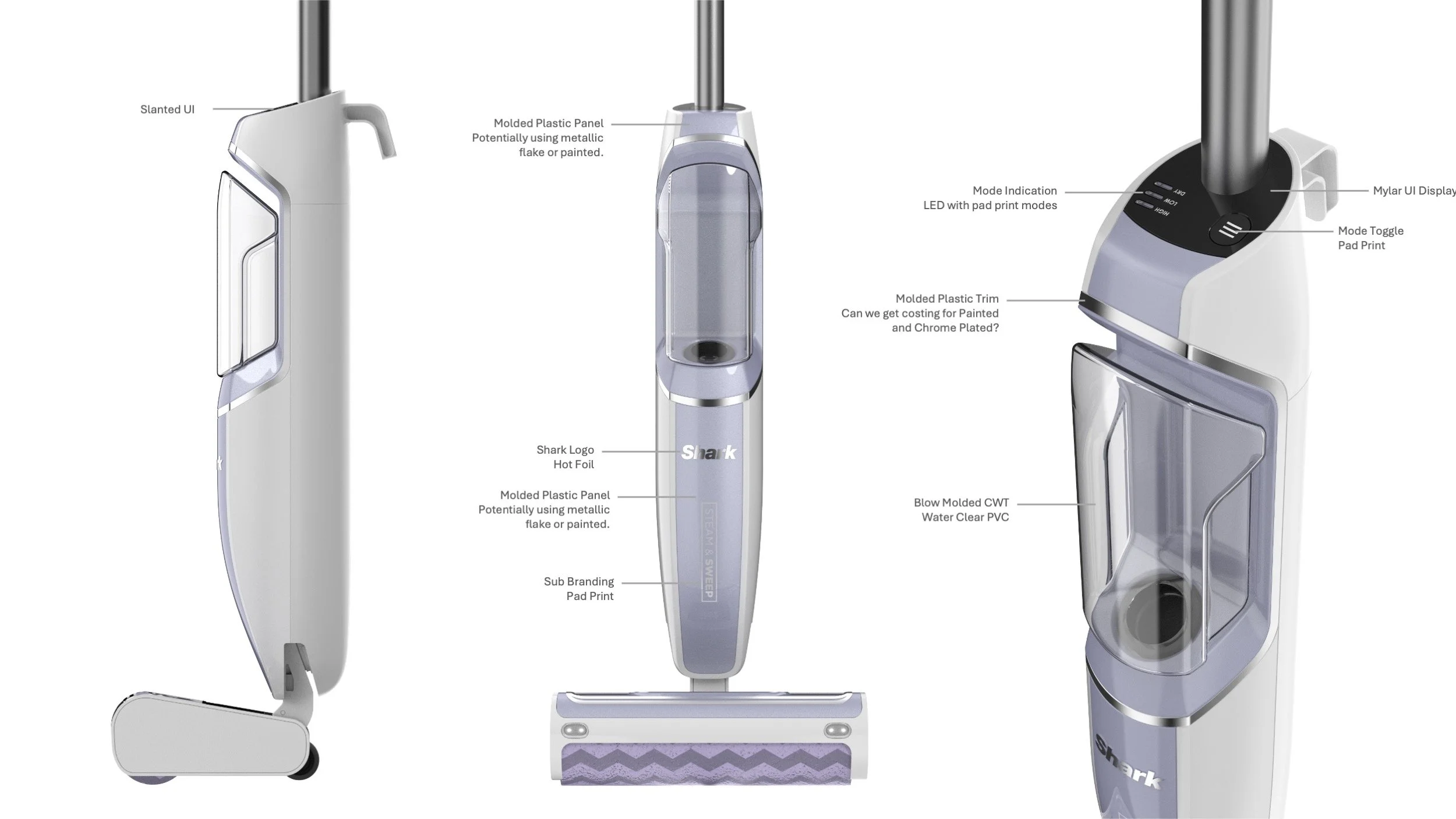

SteamSweep - P2 ID Concept Explorations

The P2 phase explored multiple new IDs that worked to improve engineering and manufacturing feasibility, and push the design to be more iconic, and new to the category.

SteamSweep - P2 ID

The P2 design was refined and established the final design gesture, garnering leadership excitement, and cross-functional alignment.

SteamSweep - SKU Variation

The teams were challenged to expand to more international markets, leading ID to investigate SKU extension opportunities.

SteamSweep - P3 ID

The design was further refined for performance optimizations, improved UX, and final design CAD submission.

SteamSweep - TRA Refinement

Final design refinements and embellishments approved for tooling.

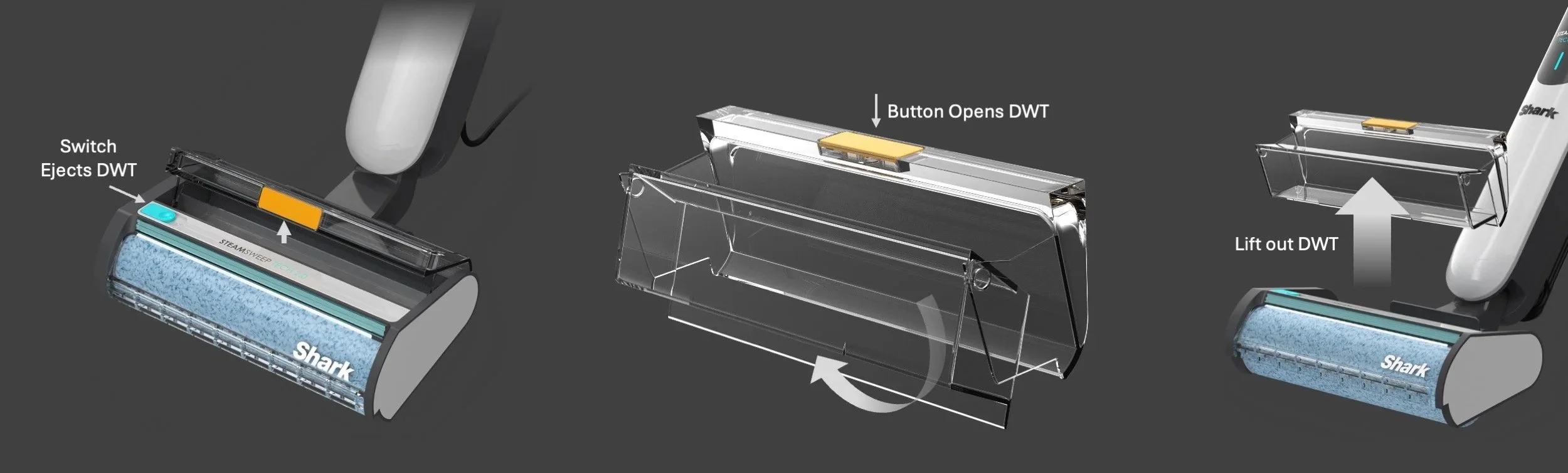

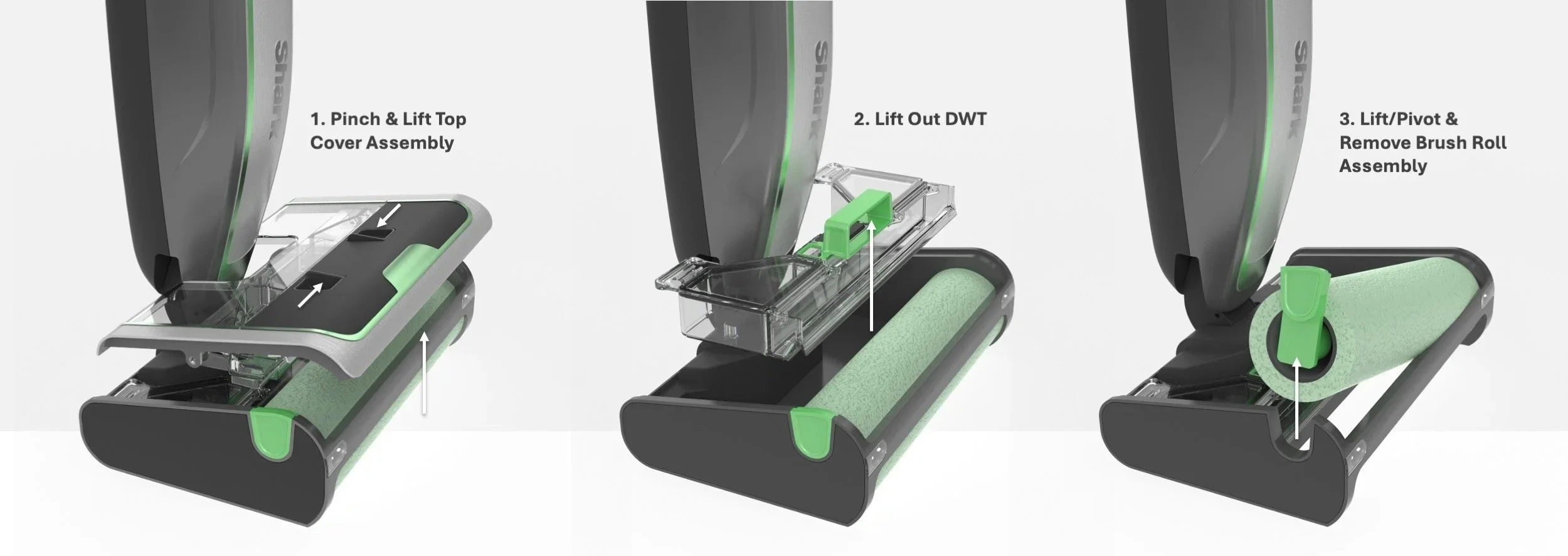

SteamSweep - Initial Nozzle UX Concept

The SteamSweep nozzle is a shared platform with the HydroSweep project. The nozzles fundamentally operate the same, but the top covers are differentiated in their plumbing and componentry. The key to the design is the scrubbing and debris collection all happen at the floor head. The debris pickup relies on the brush roll to mechanically flick debris into the collection bin while also utilizing the spinning brush roll material for floor agitation/mopping. The nozzle development was a constant design challenge that needed full collaboration between design, engineering, and product development.

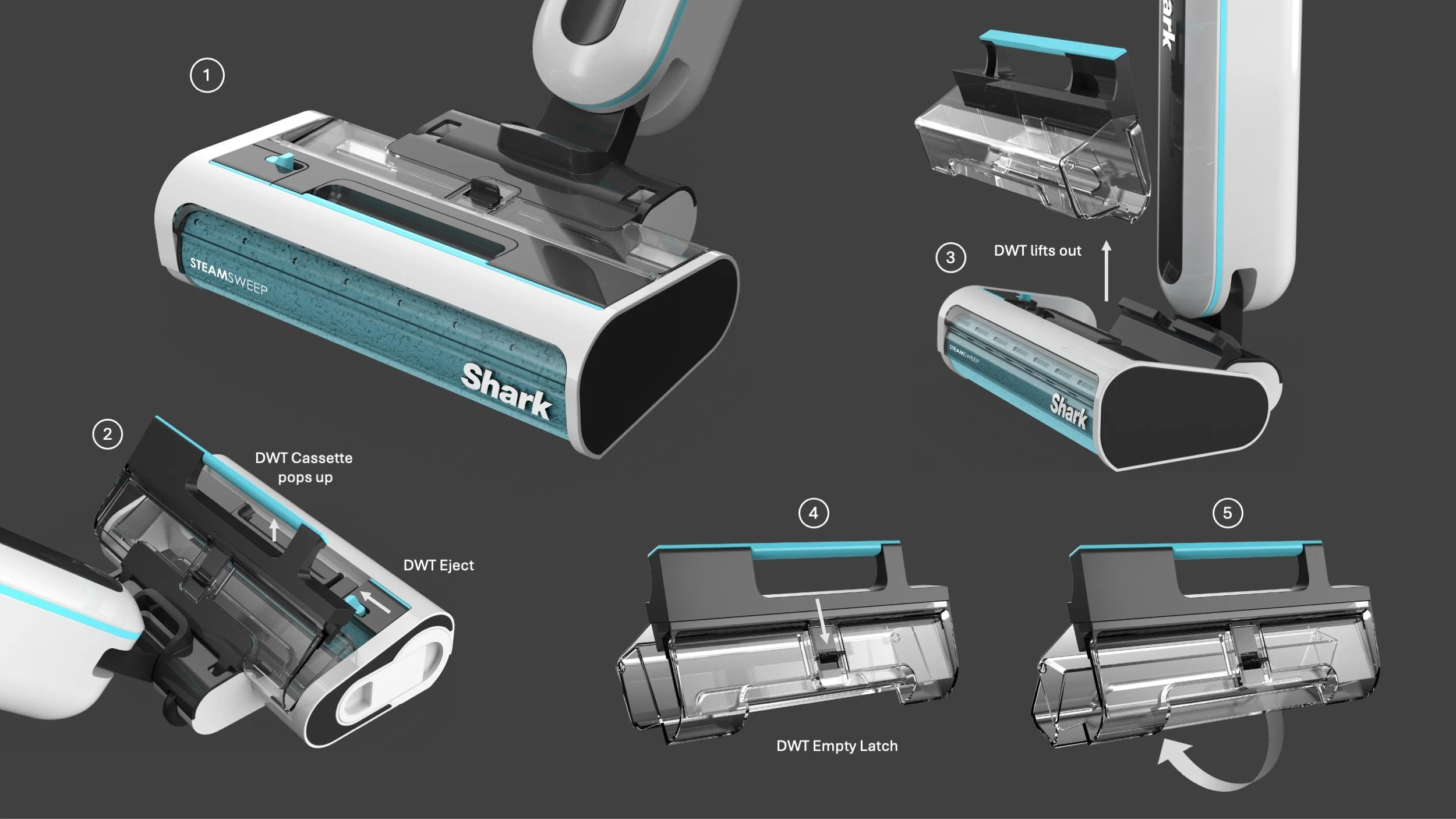

SteamSweep - P1 Nozzle Design Concept

Early concepts explored a “cassette” style interaction where the debris bin pops up and lifts out.

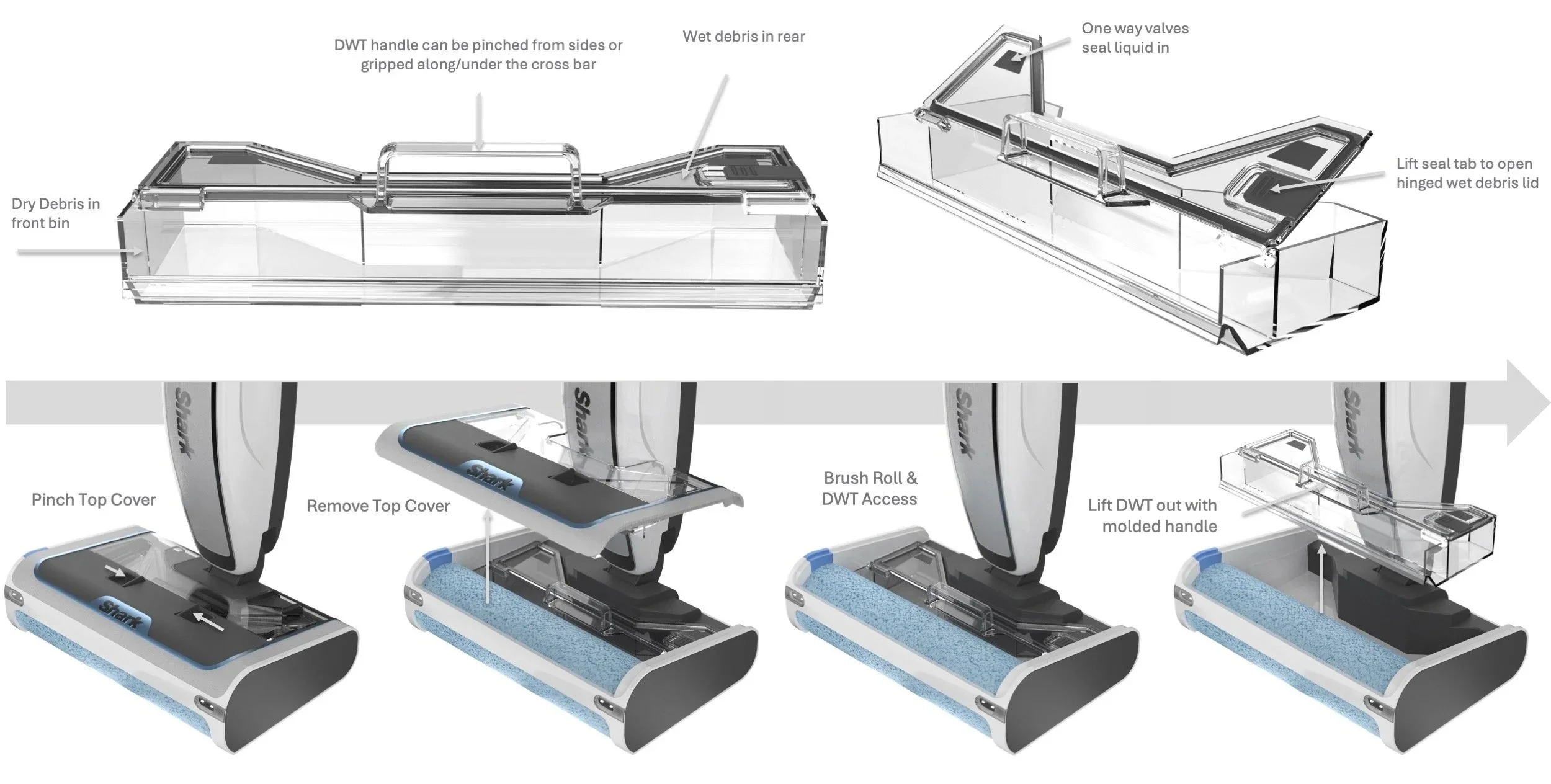

SteamSweep - P2 Nozzle Design Concept

In P2 the design and UX really started to take shape, introducing the removable top cover to the interaction. This presented the “key action areas” to the user, providing easy access to the brush roll and dirty water tank for maintenance after use.

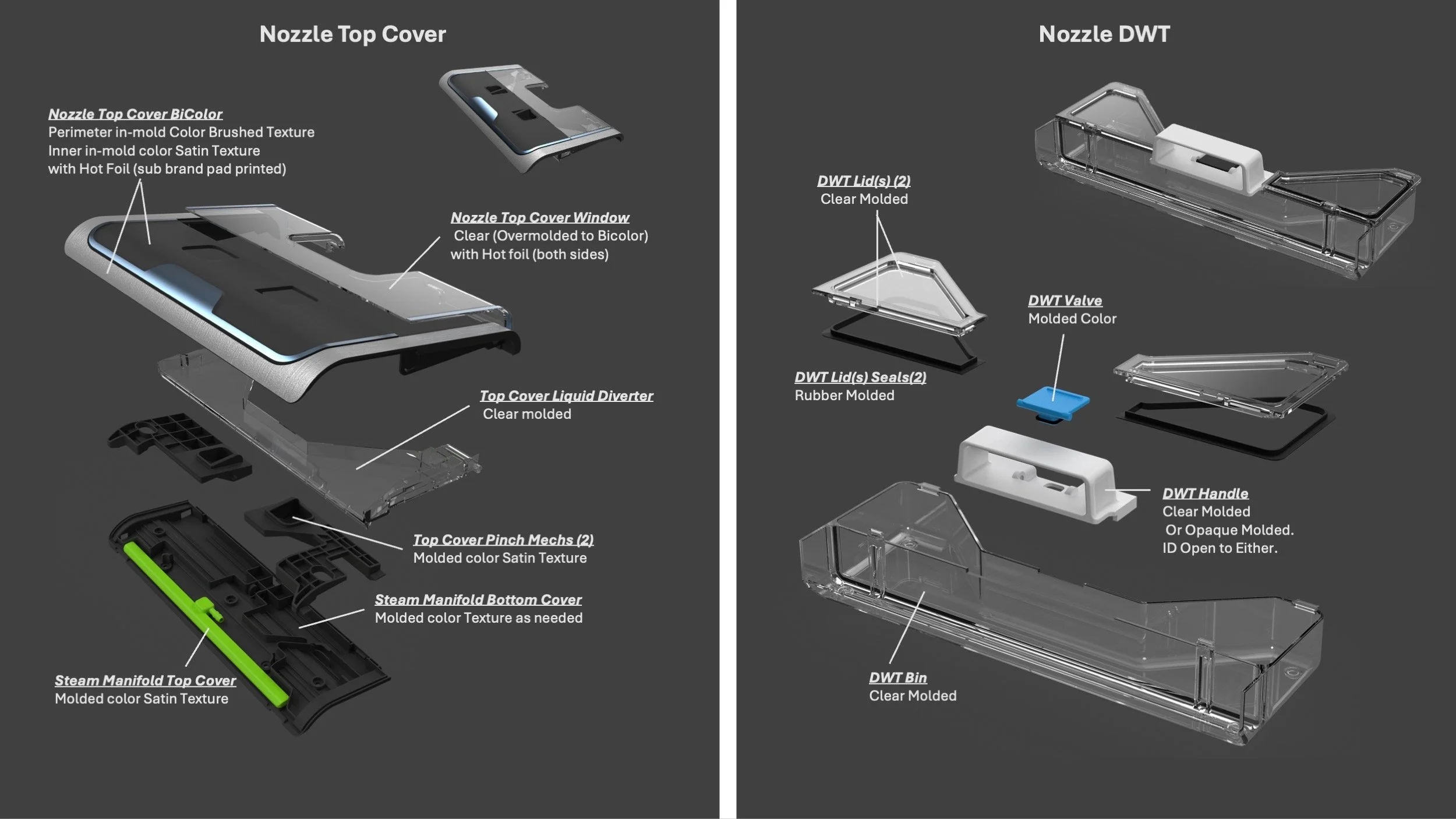

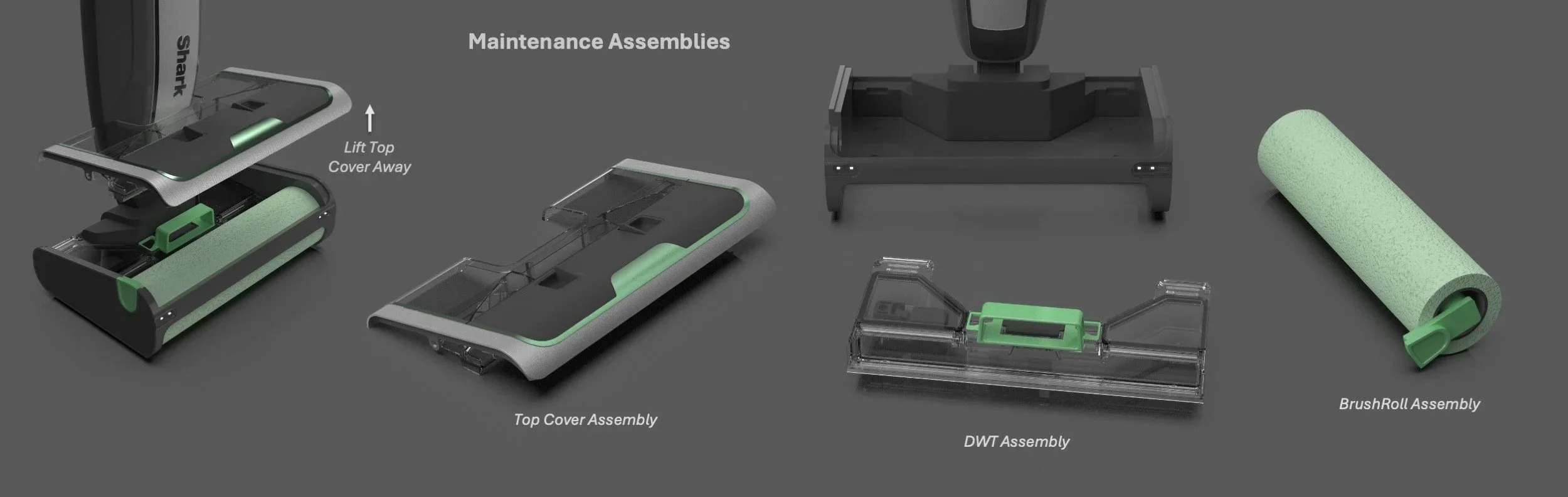

SteamSweep - Nozzle Design Construction

The SteamSweep top cover design was very complicated. We utilized a 3-stage process of bi-color + overmold, to provide a robust part that allowed for 3 different colors/finishes. while housing internals.