A case study of the product development process for industrial design at SharkNinja, through the Shark Stratos corded stick vacuum project in 2021.

Product Development Process Overview

There are 5 key stages that every project at SharkNinja must achieve to become a real product in mass production.

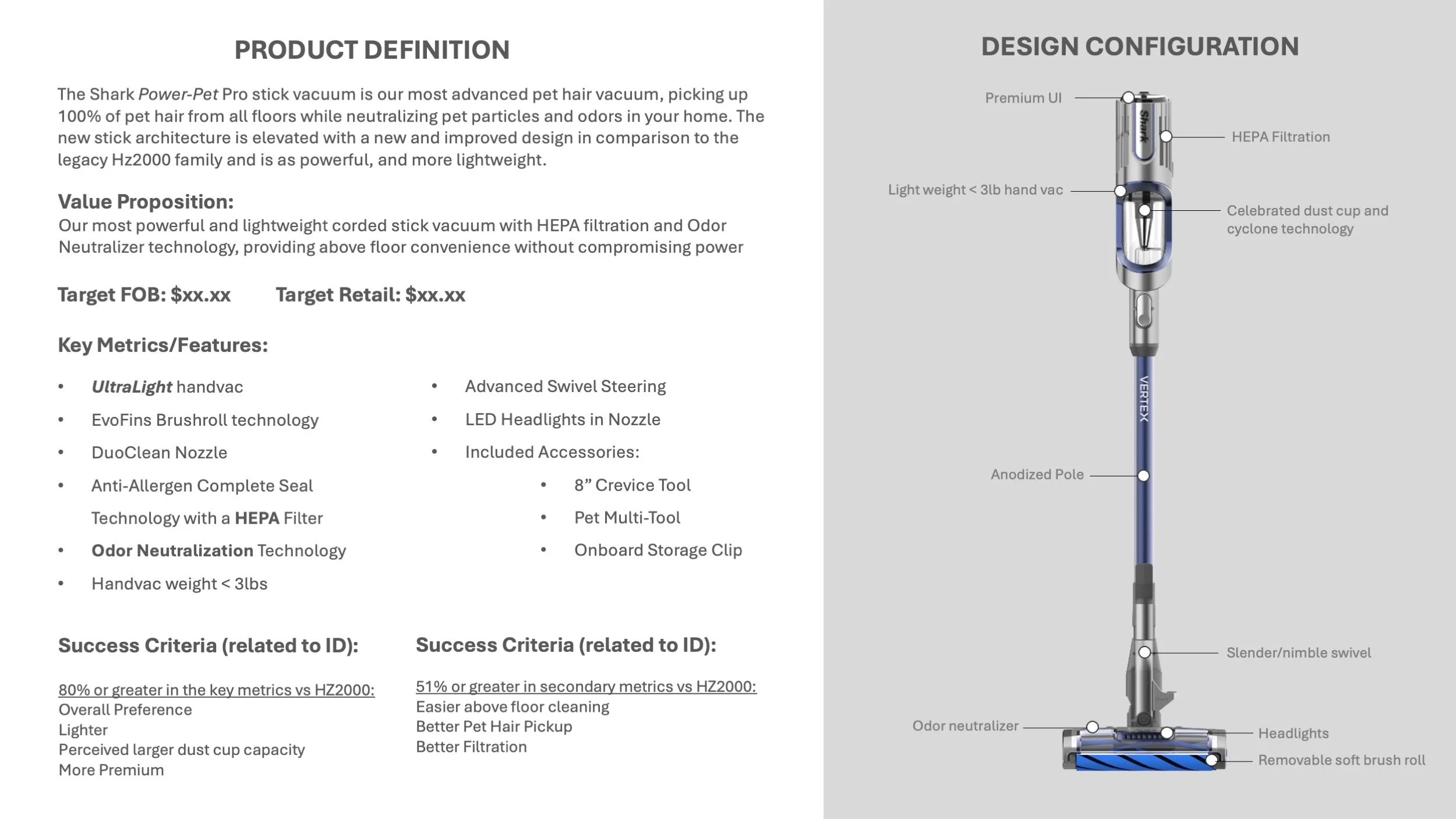

HZ3000 - Product Brief Overview

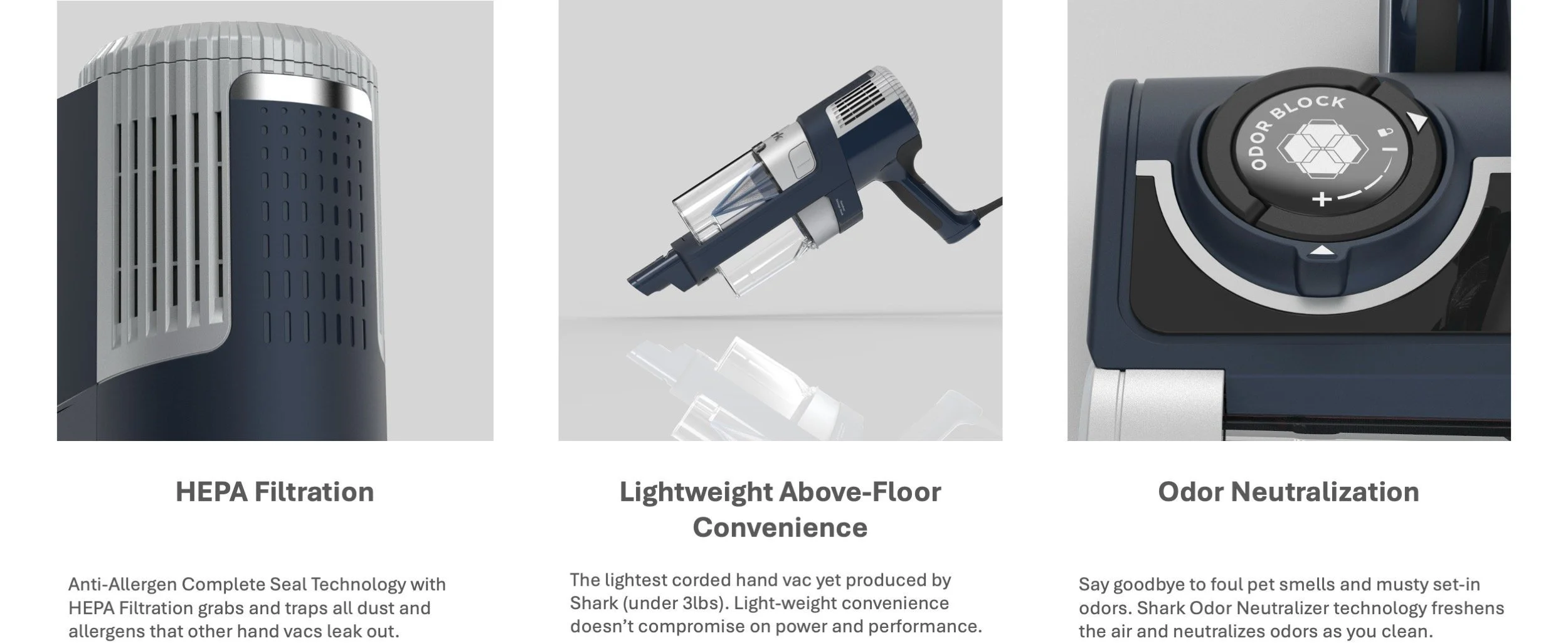

HZ3000 - Product Design Pillars

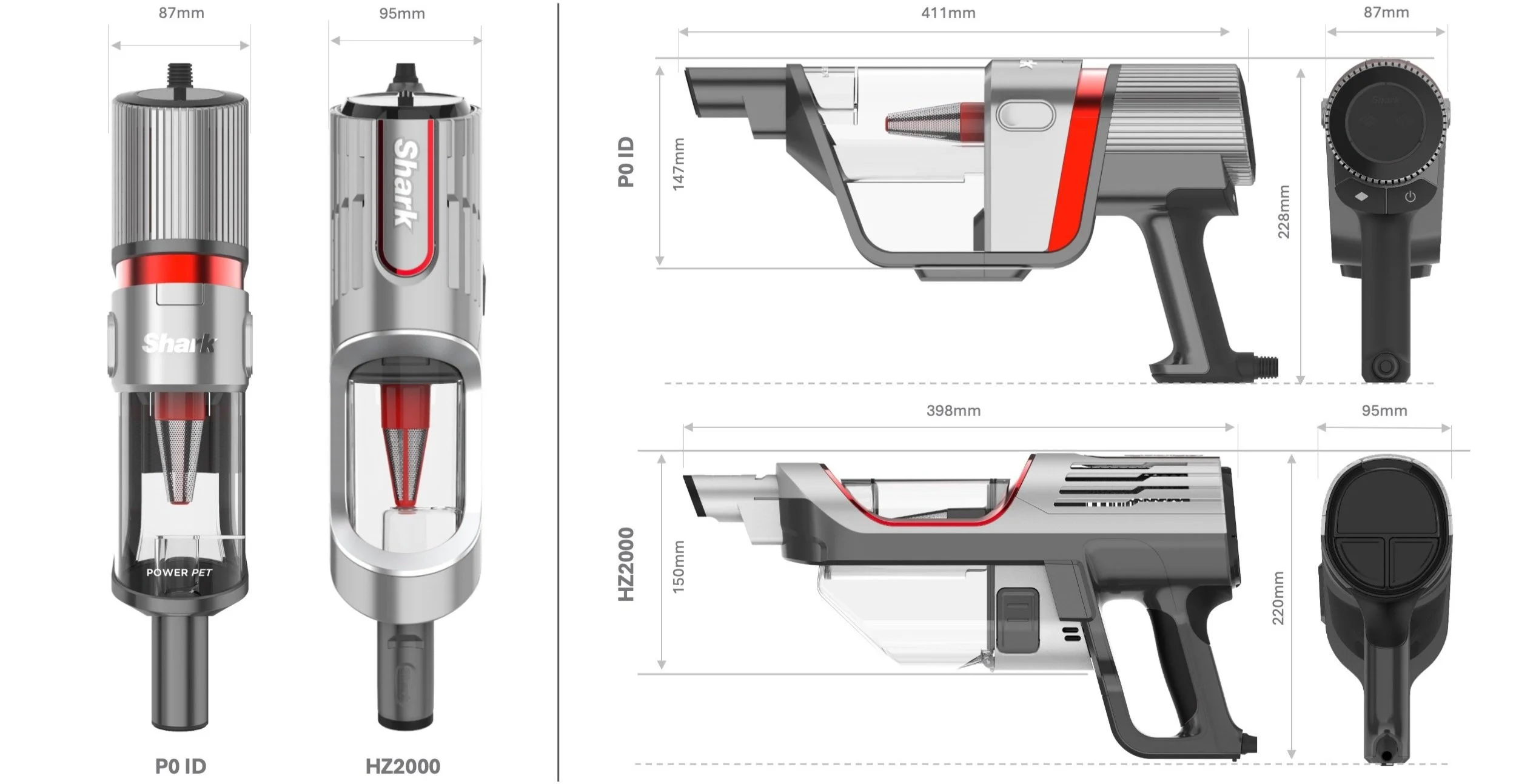

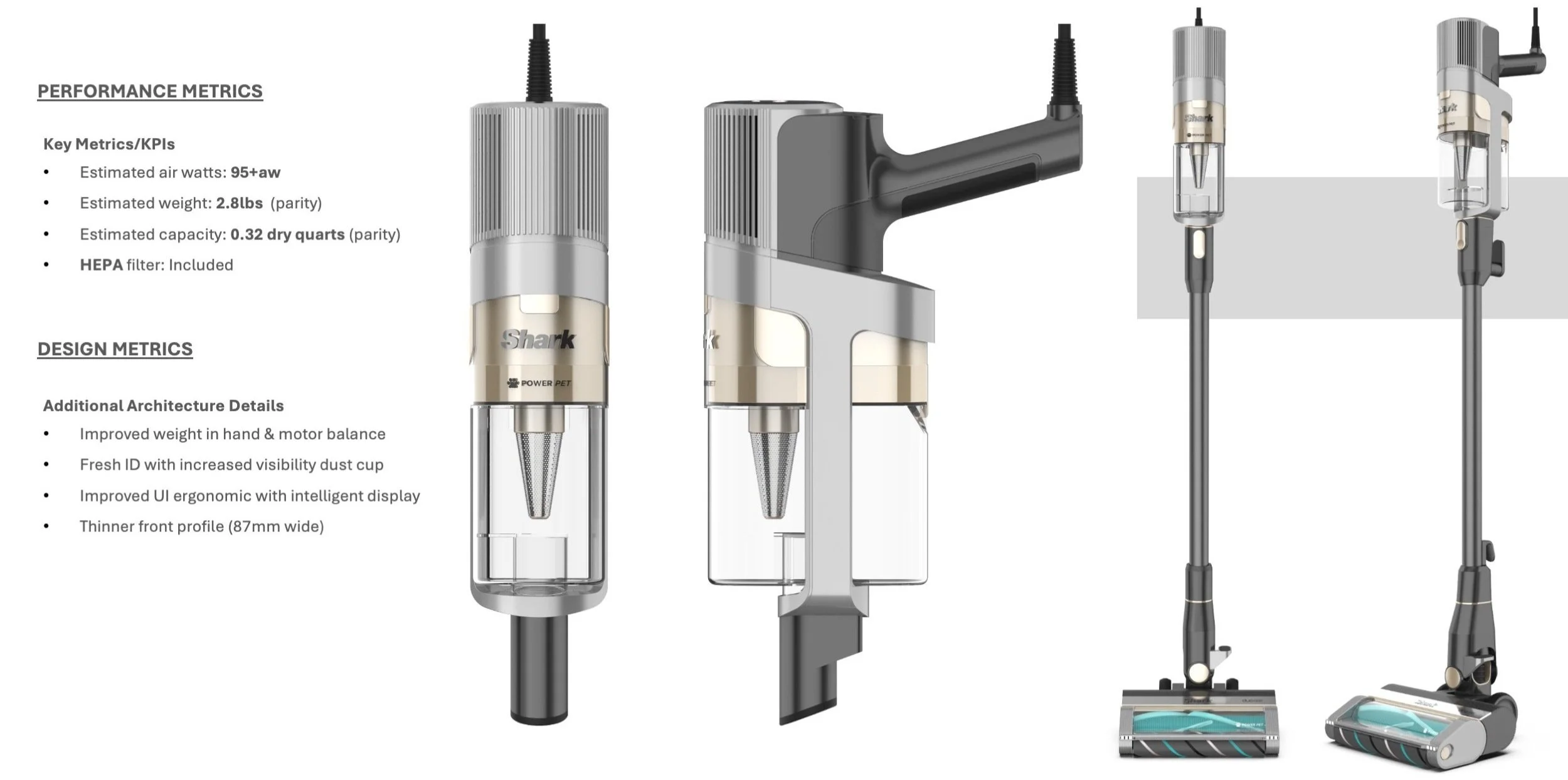

HZ3000 - P0 Engineering Underlay

The ID and Engineering teams collaborated to generate an architectural underlay containing all the key internal components that meet the performance KPIs aligned with the product development team.

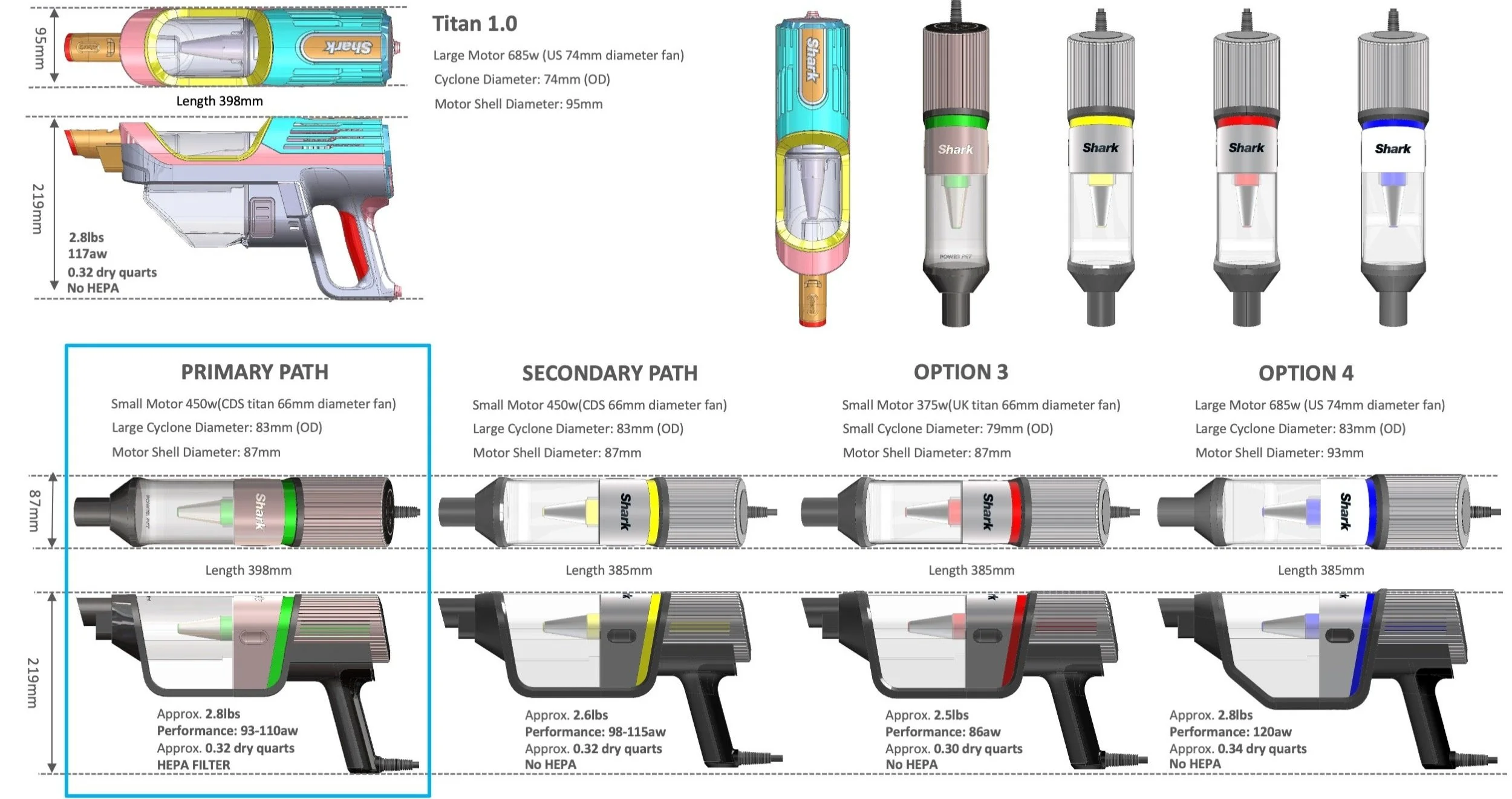

HZ3000 - P0 Size Optimization

ID worked with engineering leads to create a matrix of refined architectures that could achieve our size targets while maintaining a path to our target performance. The team aligned on a primary path that achieved a compact footprint, performative air watts, and included HEPA filtration, creating a new design that out performed the legacy hand vac (Titan 1).

HZ3000 - P0 Volume Studies

ID volume studies using transparent and opaque 3D printed parts were created to evaluate the size matrix and support the aligned primary path.

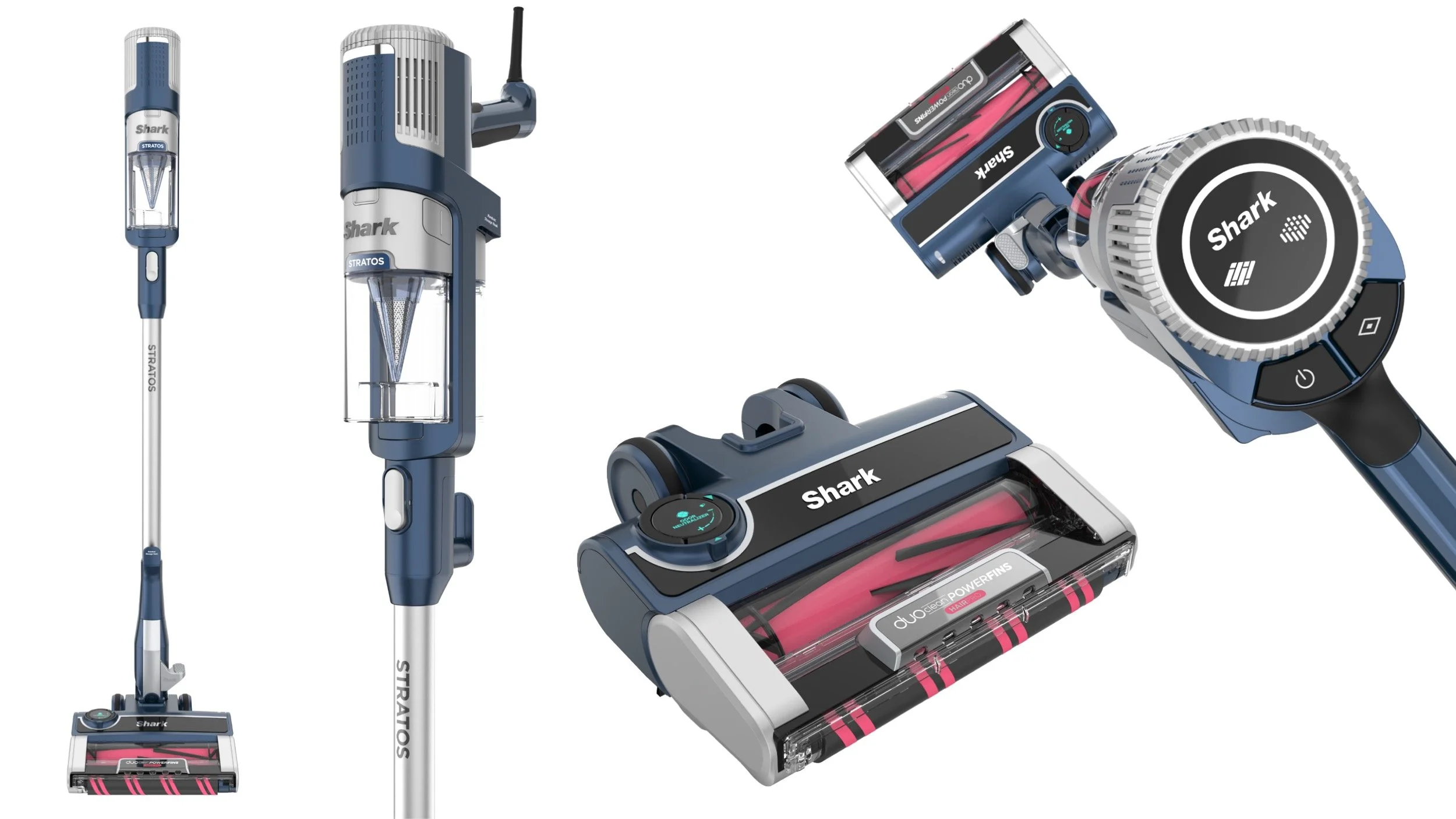

HZ3000 - P0 ID: Full Unit Overview

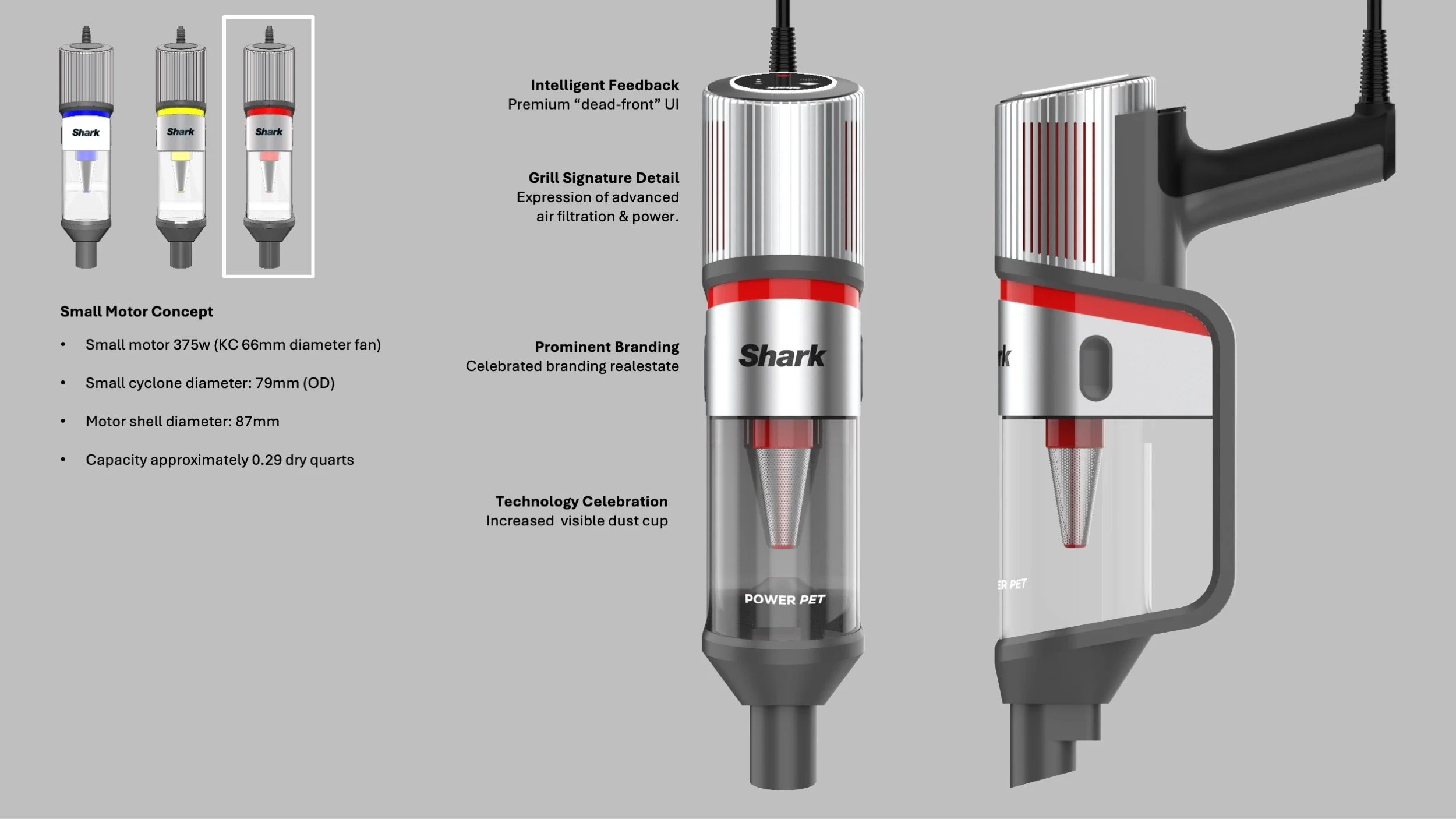

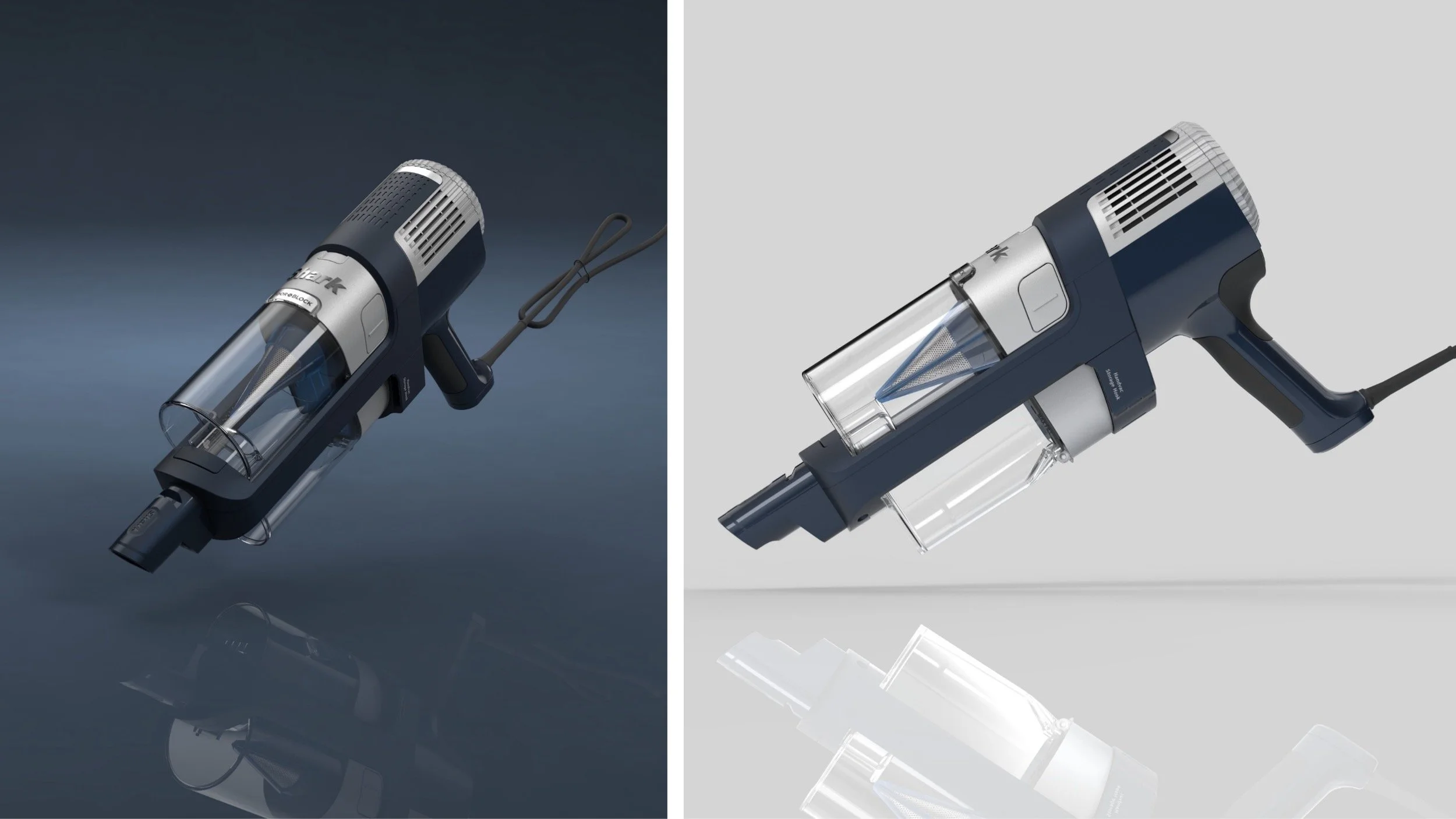

HZ3000 - P0 ID: Hand Vac

HZ3000 - P0 ID: UI

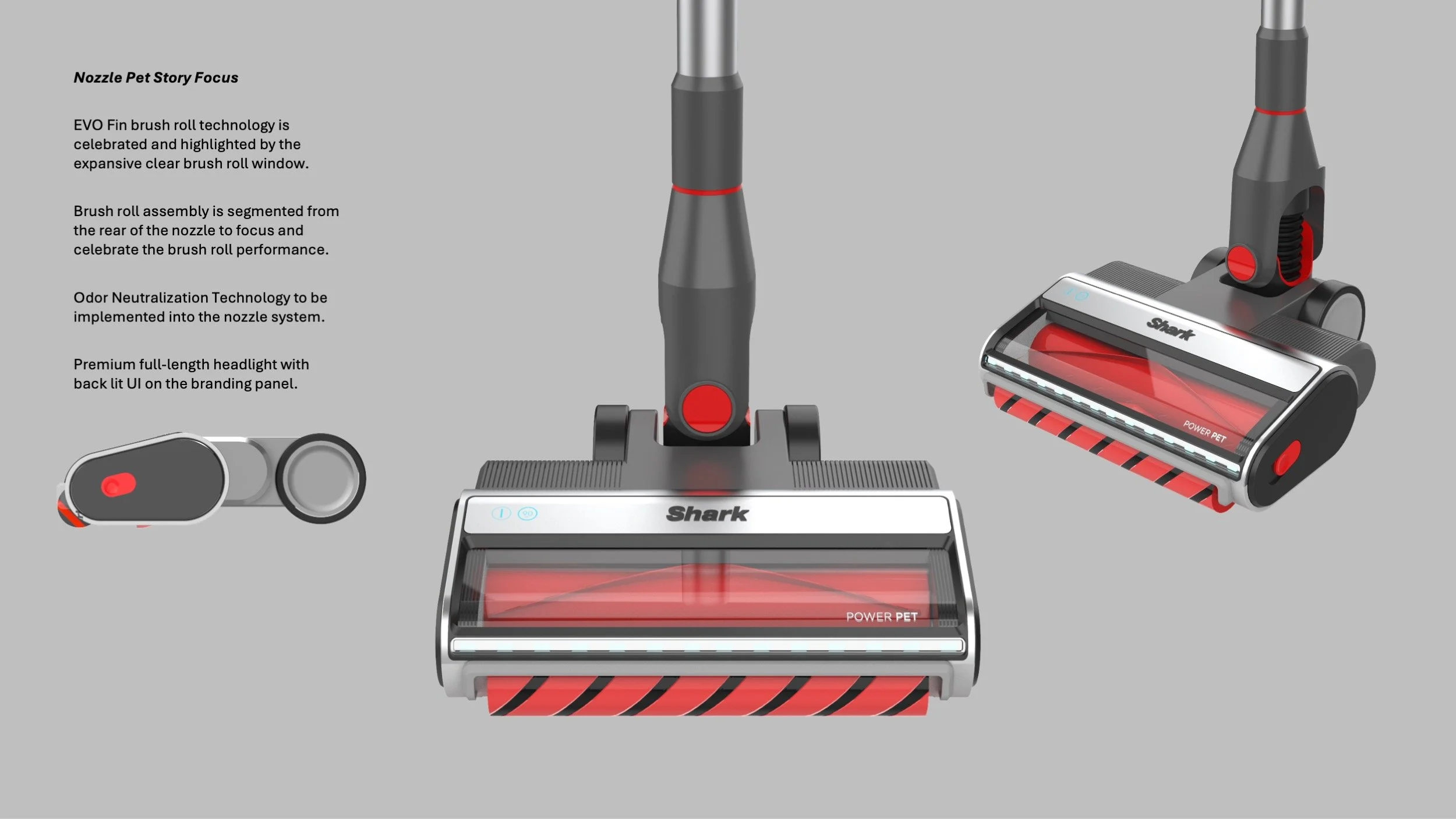

HZ3000 - P0 ID: Floor Nozzle

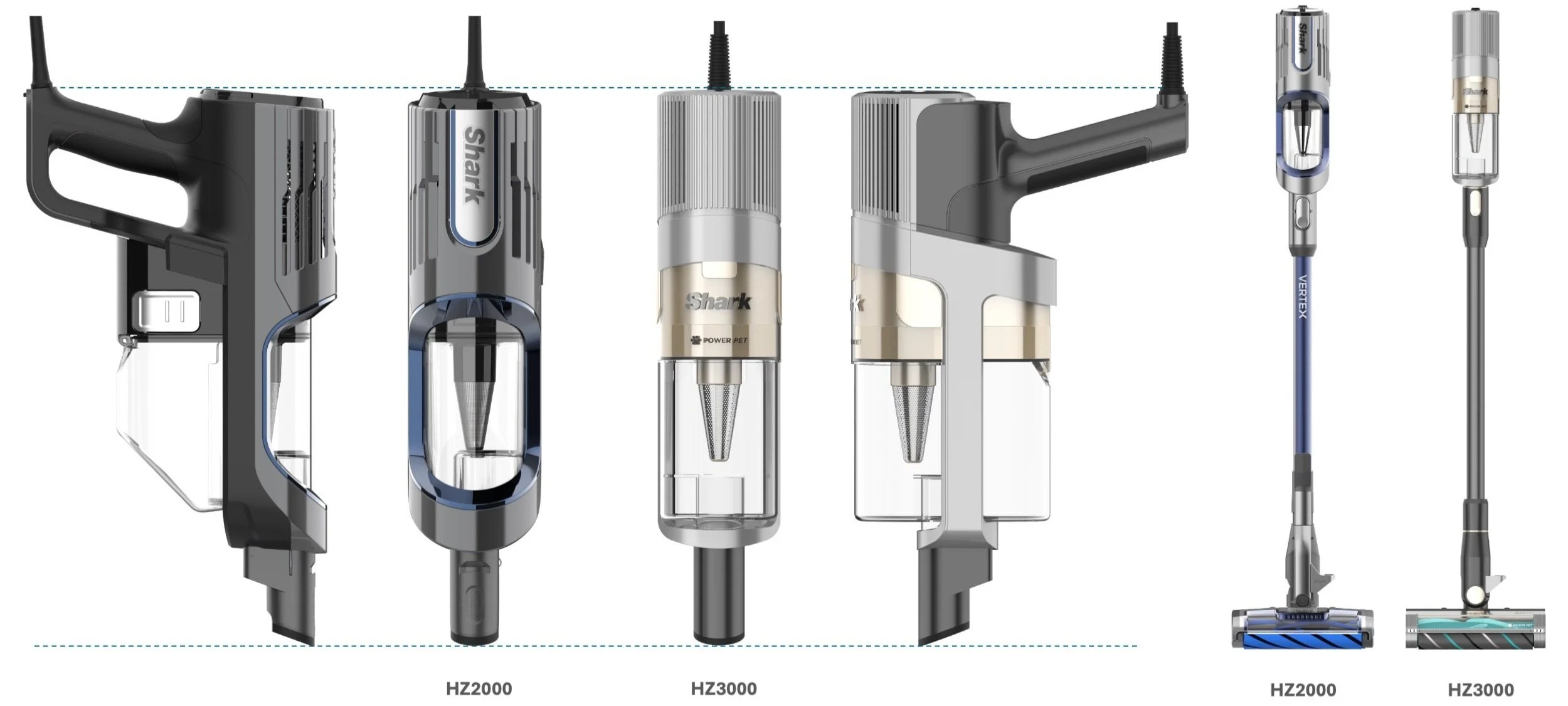

HZ3000 - P0 ID: Hand Vac Size Comparision

HZ3000 - P0 ID: Concept Animations

HZ3000 - P0 ID: User Journey

The new hand vac design introduced the “clean-break” dust cup architecture which needed further vetting regarding the UX. The team needed to ensure that the user journey was optimal and provided the best possible user experience.

HZ3000 - P0 ID: Competitive Shelf Lineup

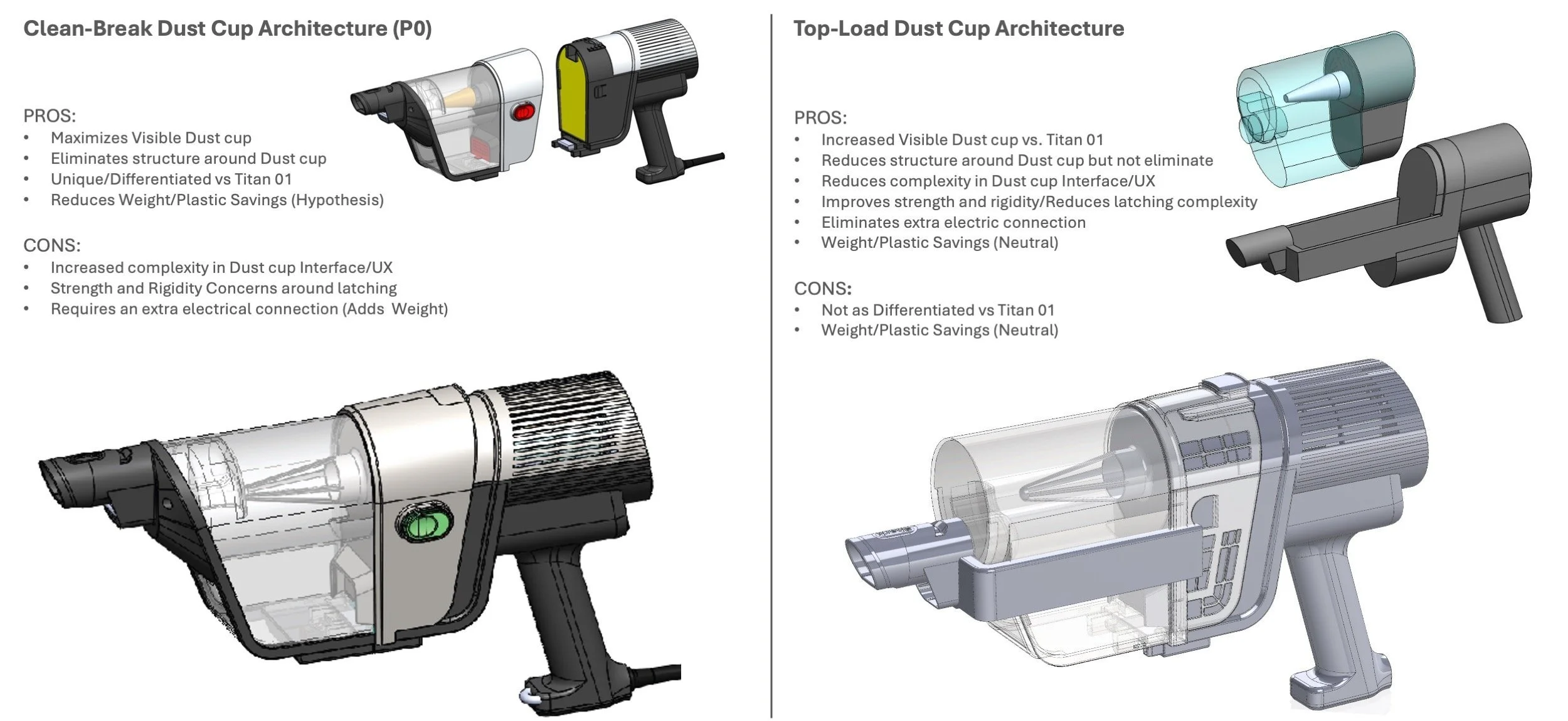

HZ3000 - P1 ID: Architectural Pivot

Upon reviewing the initial P0 functional samples, we found the “clean-break” architecture had extreme failures regarding strength. The footprint would need to grow considerably to relieve these issues, and there was growing skepticism in that the architecture negatively impacted the user journey. The team needed to pivot and look at an alternative architecture that could address the growing issues.

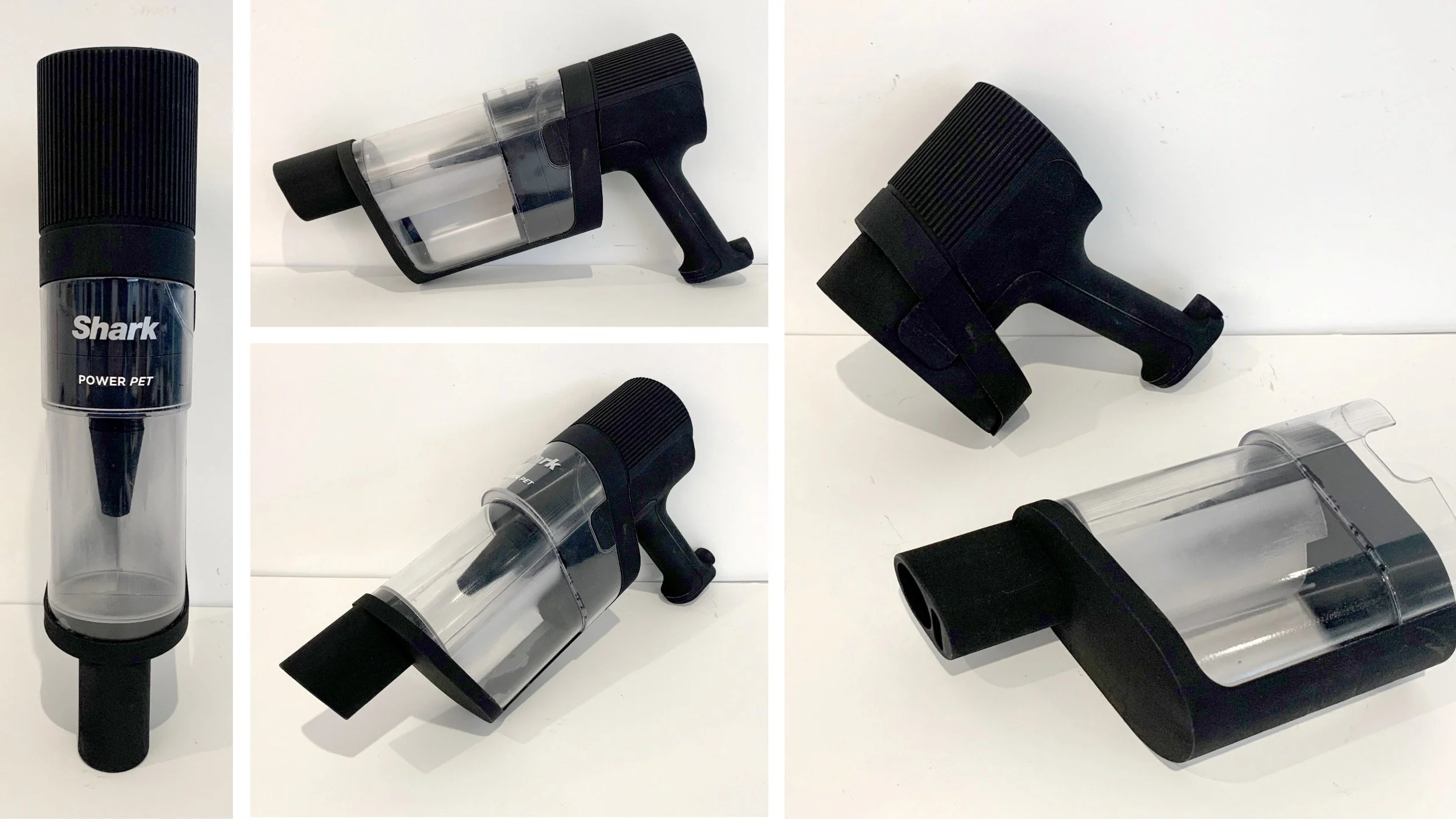

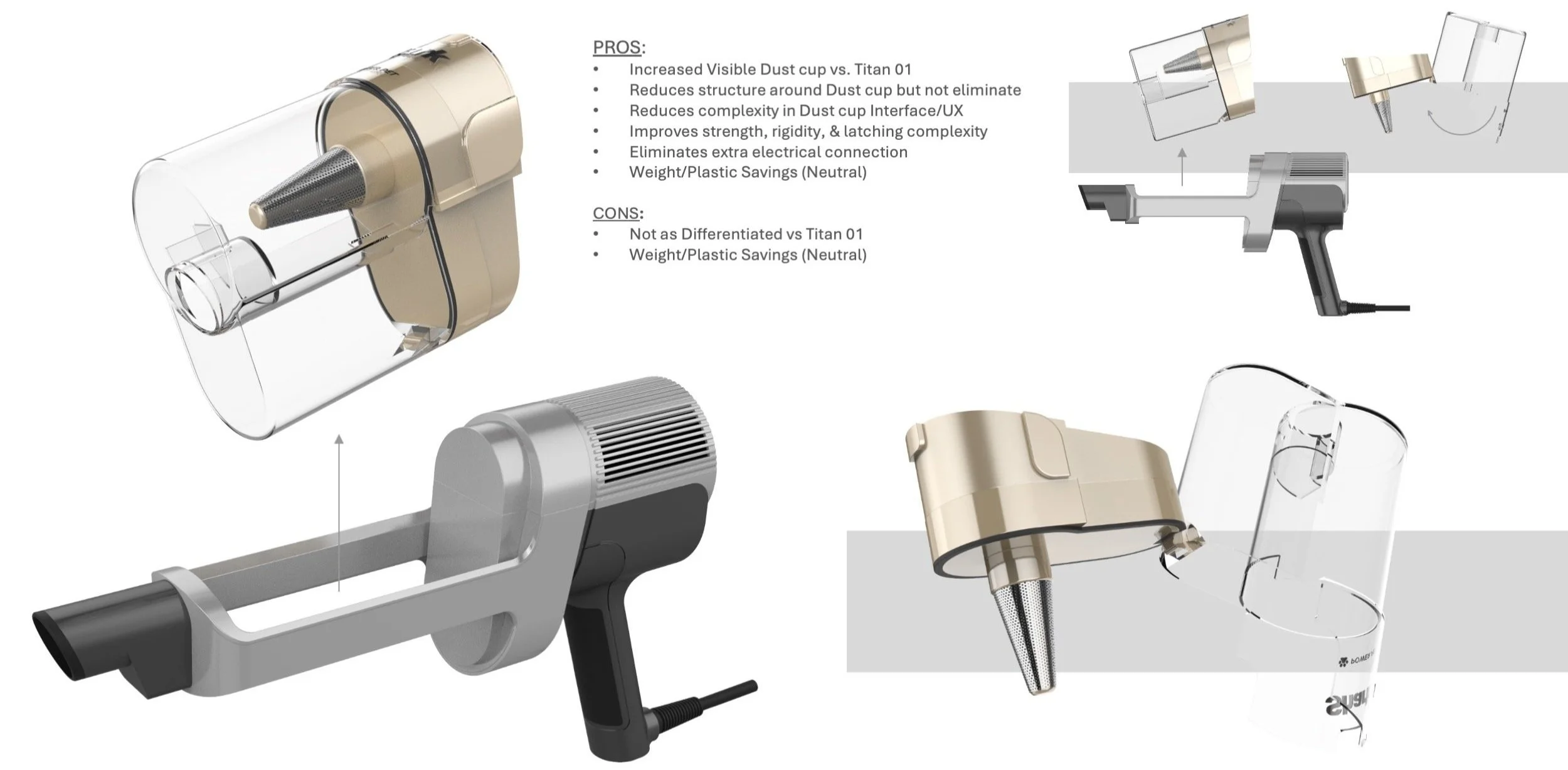

HZ3000 - P1 ID: Refined “Clean-Break” Architecture Volume Study

One last effort was made to refine the “clean break” architecture, but the high risk of viability ultimately killed the concept.

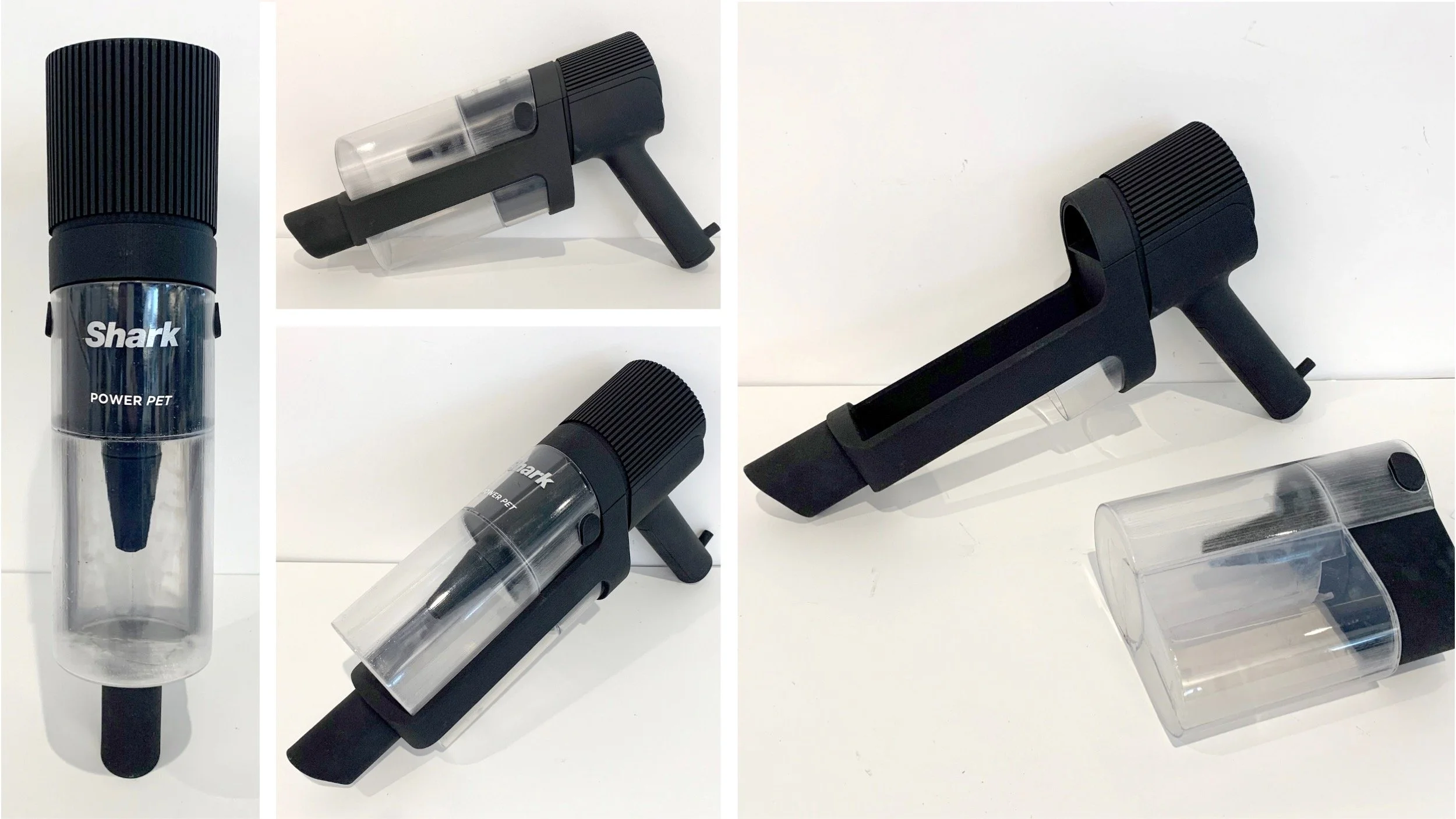

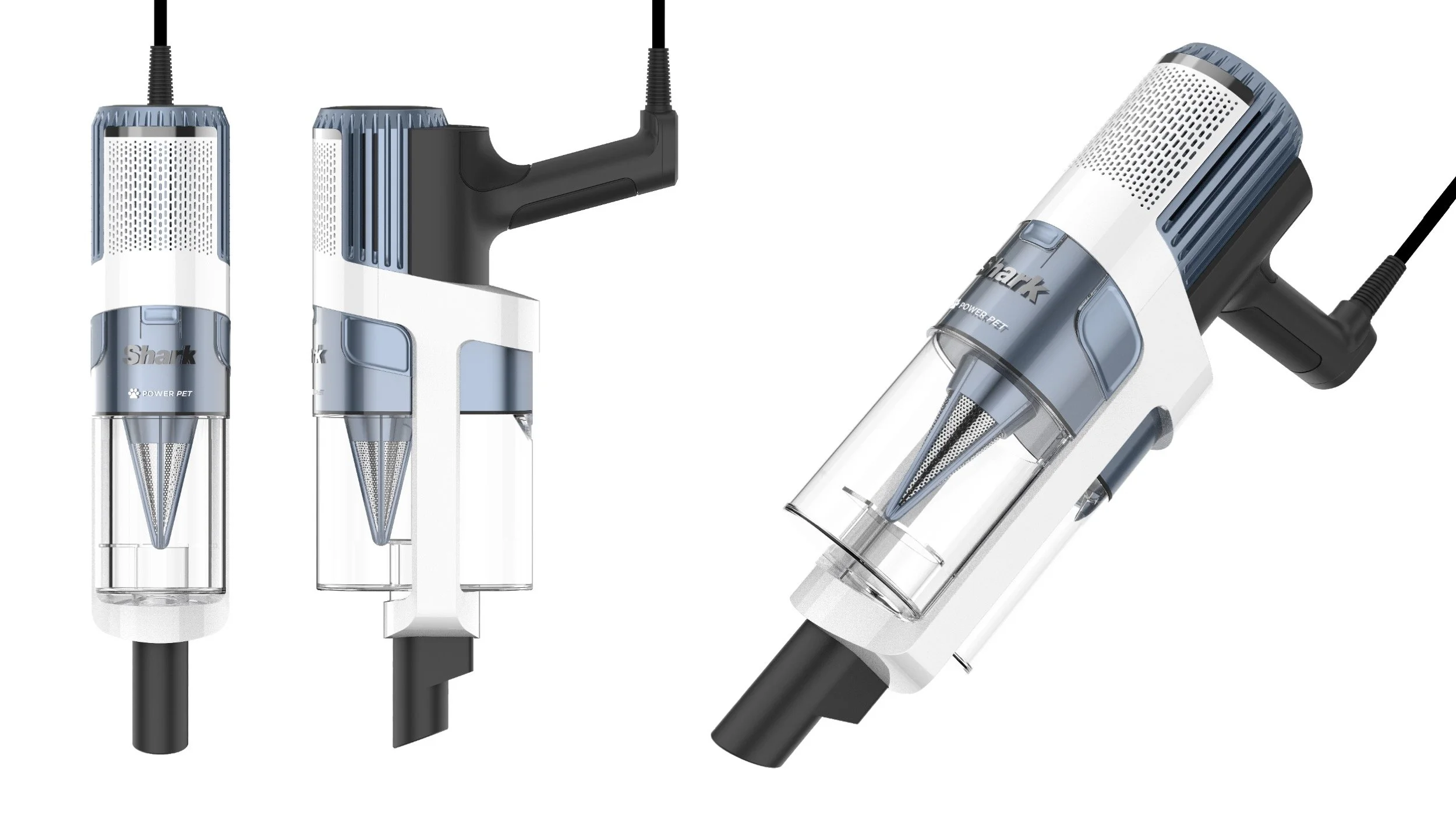

HZ3000 - P1 ID: “Top-Load” Architecture Volume Study

The new “top-load” architecture proved promising, providing an intuitive UX, while maintaining a compact footprint, and celebrated clear dust cup.

HZ3000 - P1 ID: Overview

HZ3000 - P1 ID: Hand Vac Dust Cup UX

HZ3000 - P1 ID: UI

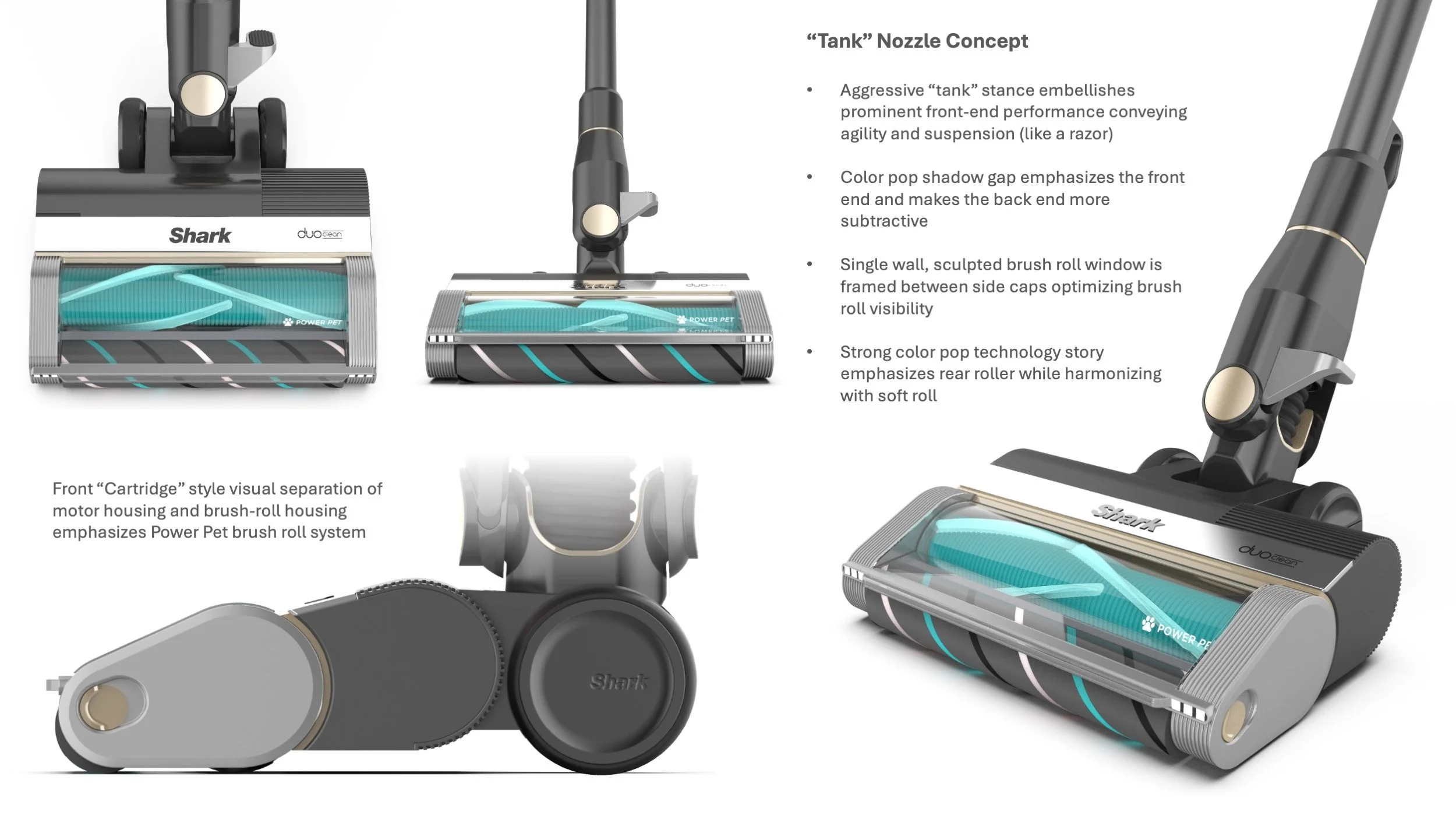

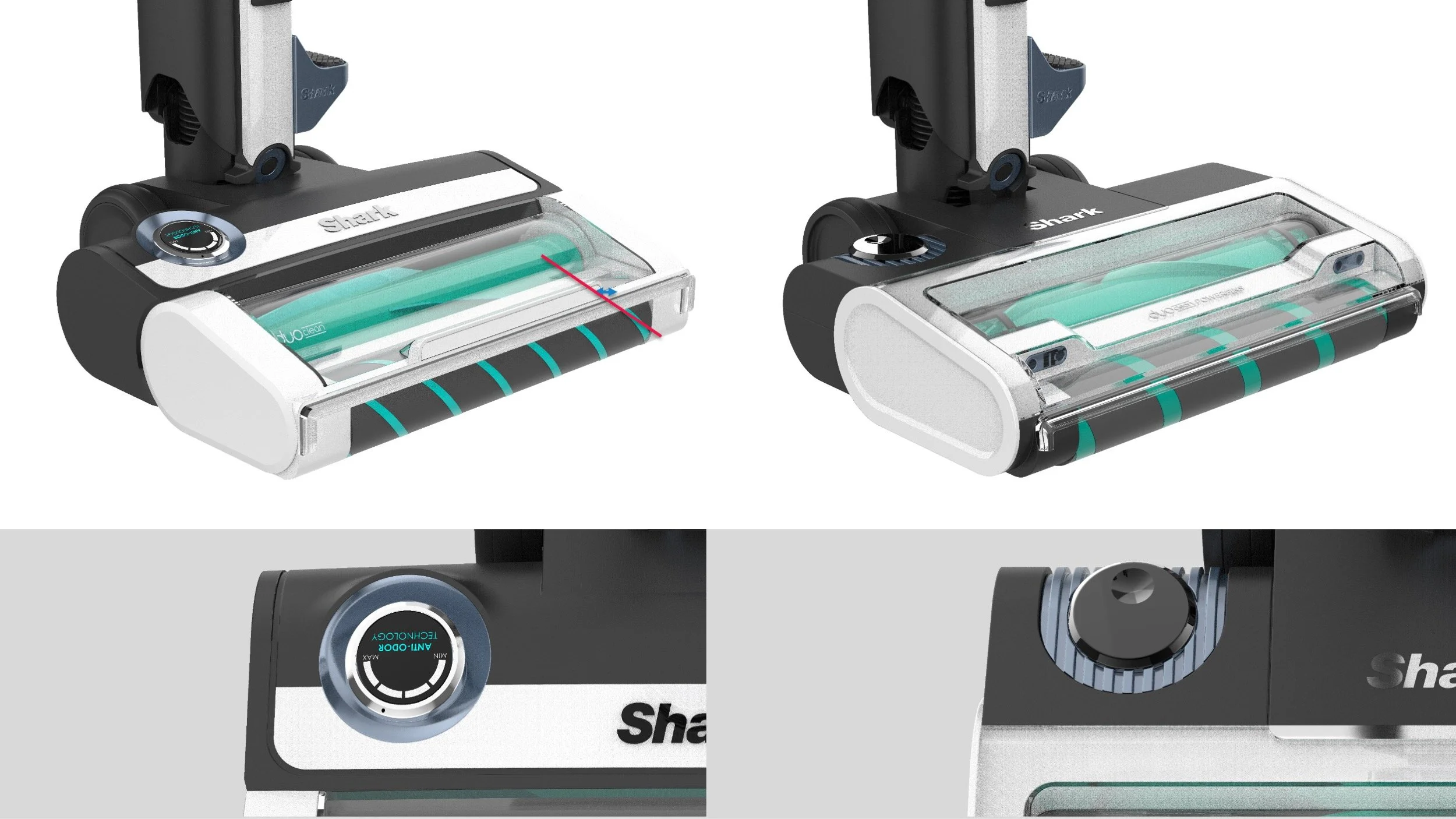

HZ3000 - P1 ID: Floor Nozzle

HZ3000 - P1 ID: Design Comparison

HZ3000 - P2 ID: Concept Development

Upon review of the P1 ID, leadership directed the ID team to push the “power, HEPA filtration, and odor neutralization” story through the design. The P1 ID was too subtle and understated. The celebrated clear dust cup was working, but the branding and grill exhaust zones needed to be pushed further.

HZ3000 - P2 ID: Hand Vac Concept Development

HZ3000 - P2 ID: Floor Nozzle Development

HZ3000 - P2 ID: Hand Vac Branding Concept Options

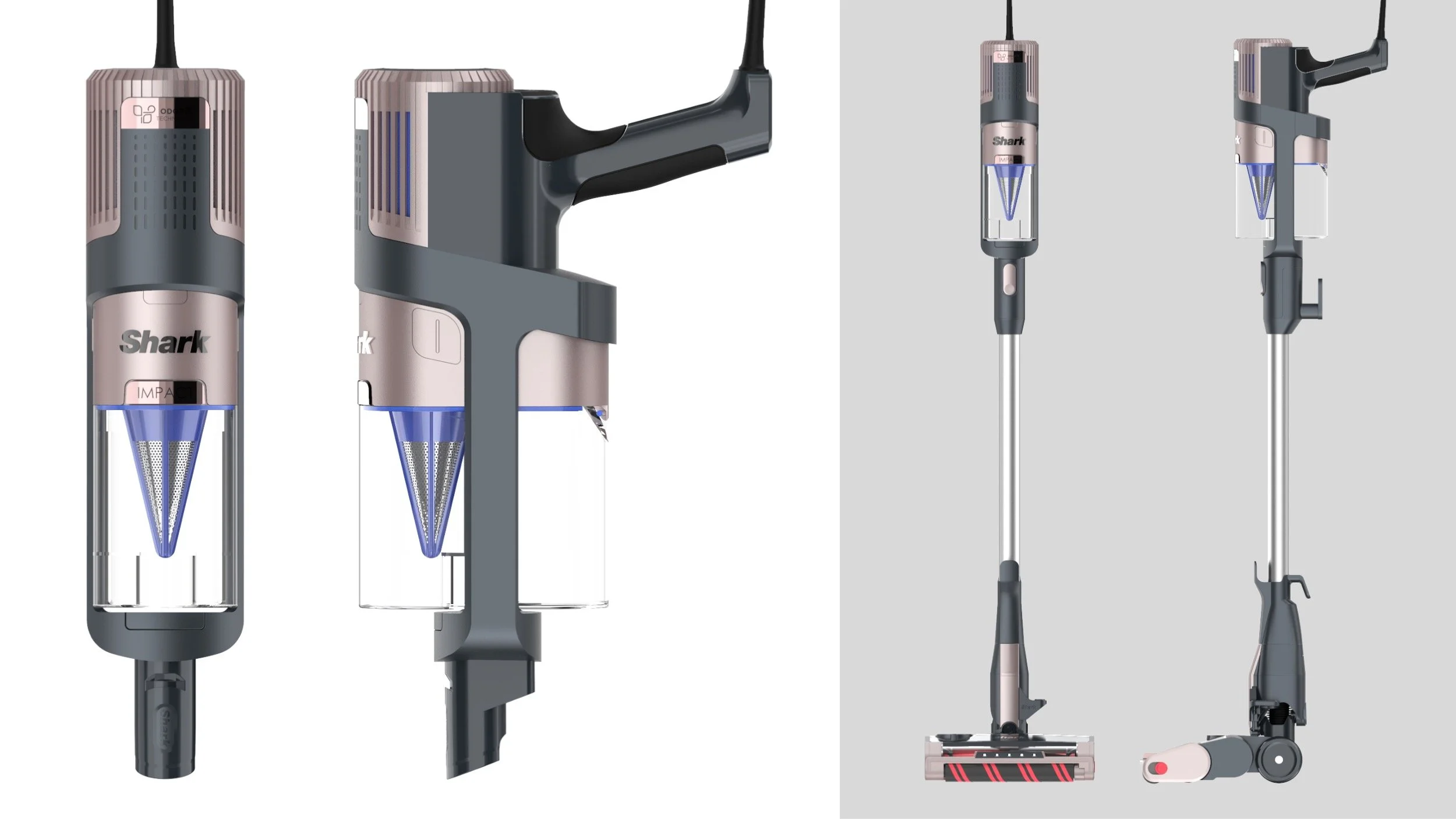

HZ3000 - P3 ID: Concept Refinement

P2 development helped inform and evolve the original ID intent, coming to a culmination at P3, the final development phase before freezing the design for TRA (steel cut).

HZ3000 - P3 ID: Concept Refinement

HZ3000 - P3 ID: Concept Refinement

HZ3000 - P3 ID: Concept Refinement

HZ3000 - P3 ID: Concept Evolution

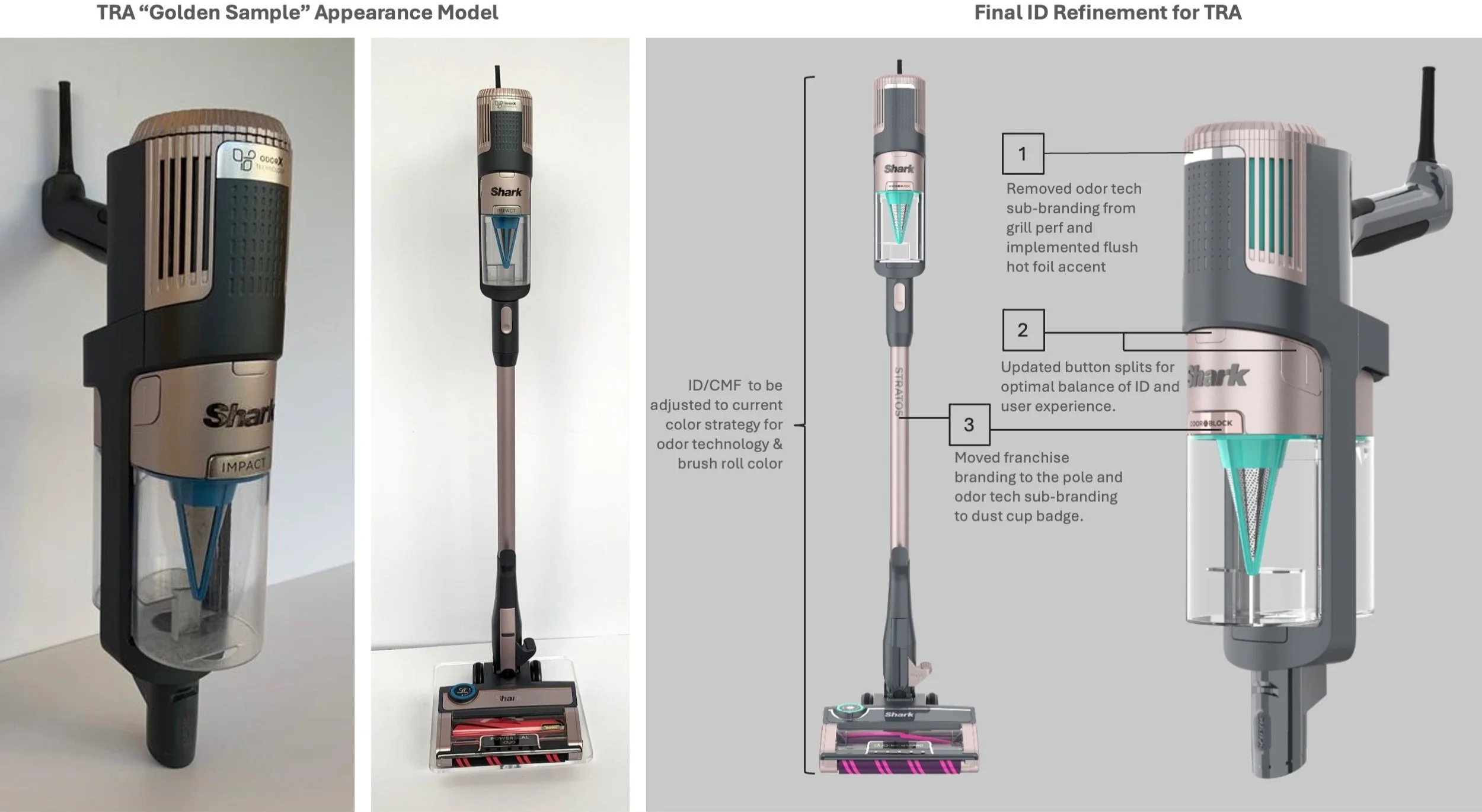

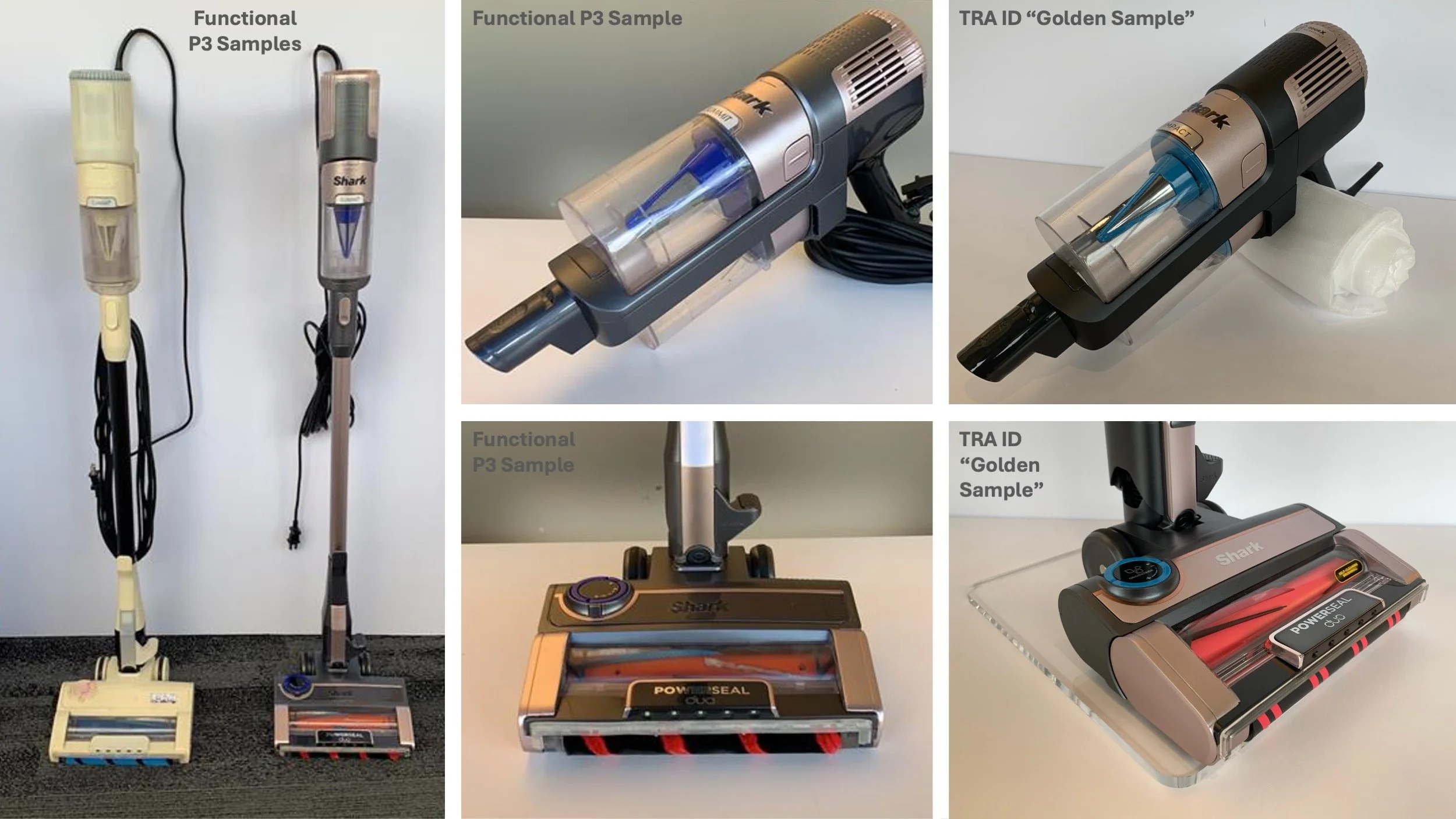

HZ3000 - TRA ID: “Golden Sample” Model Review

Ahead of TRA, ID commissioned a high fidelity “golden sample” appearance model to review the ID with leadership for final approval. Upon review, final adjustments were identified to be implemented and verified before cutting steel.

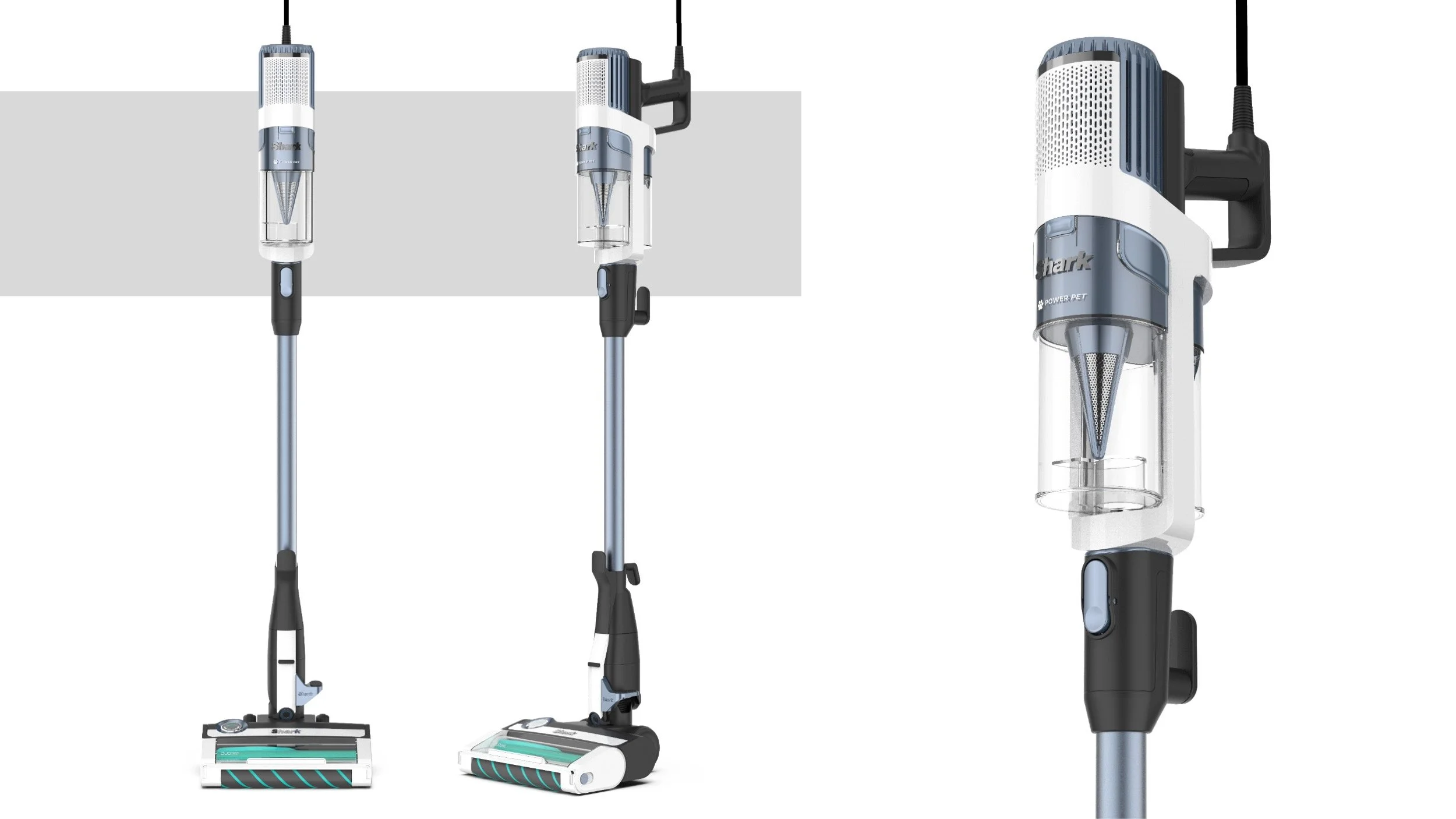

HZ3000 - TRA ID: “Golden Sample” Model & Functional P3 Sample

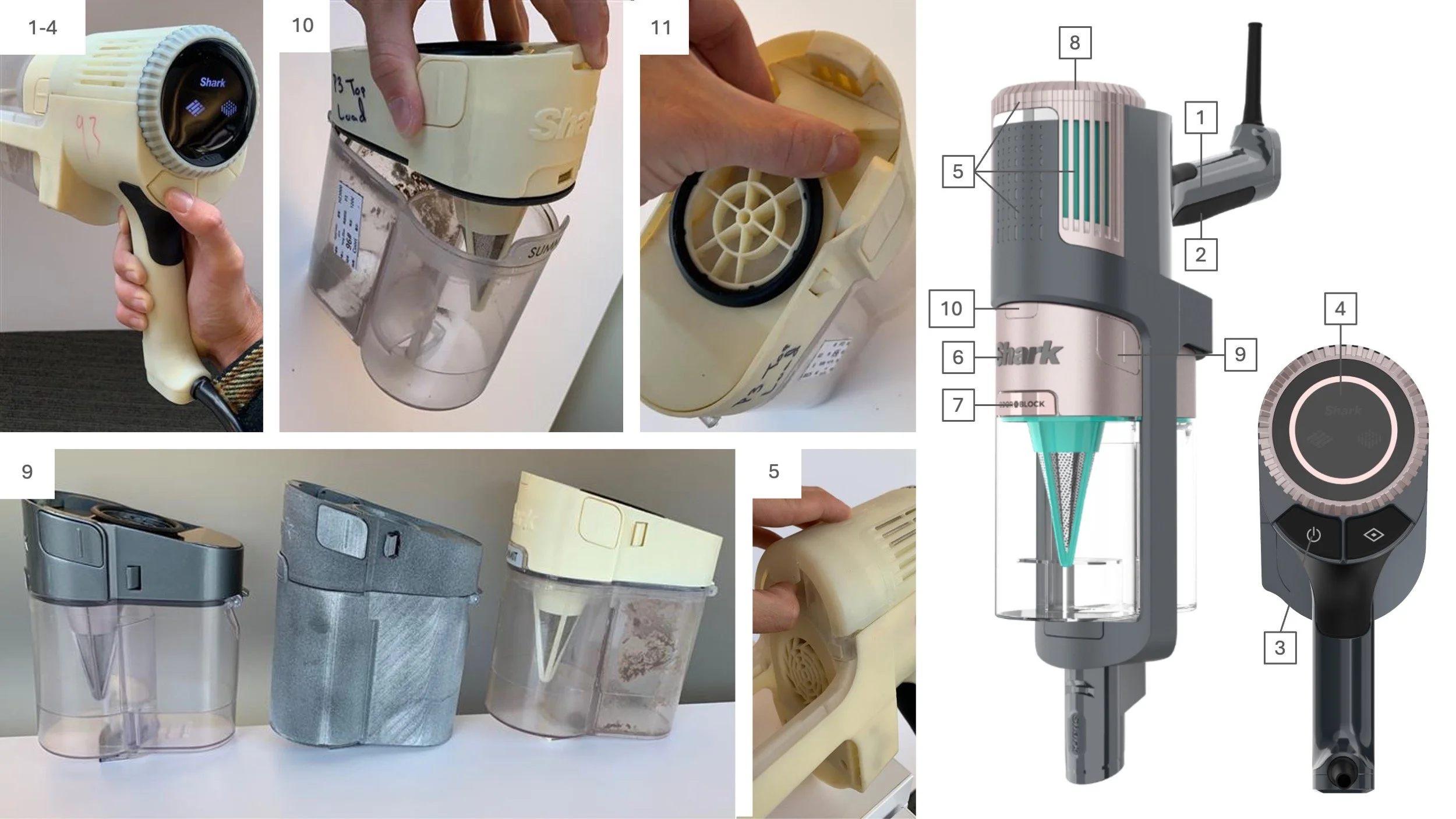

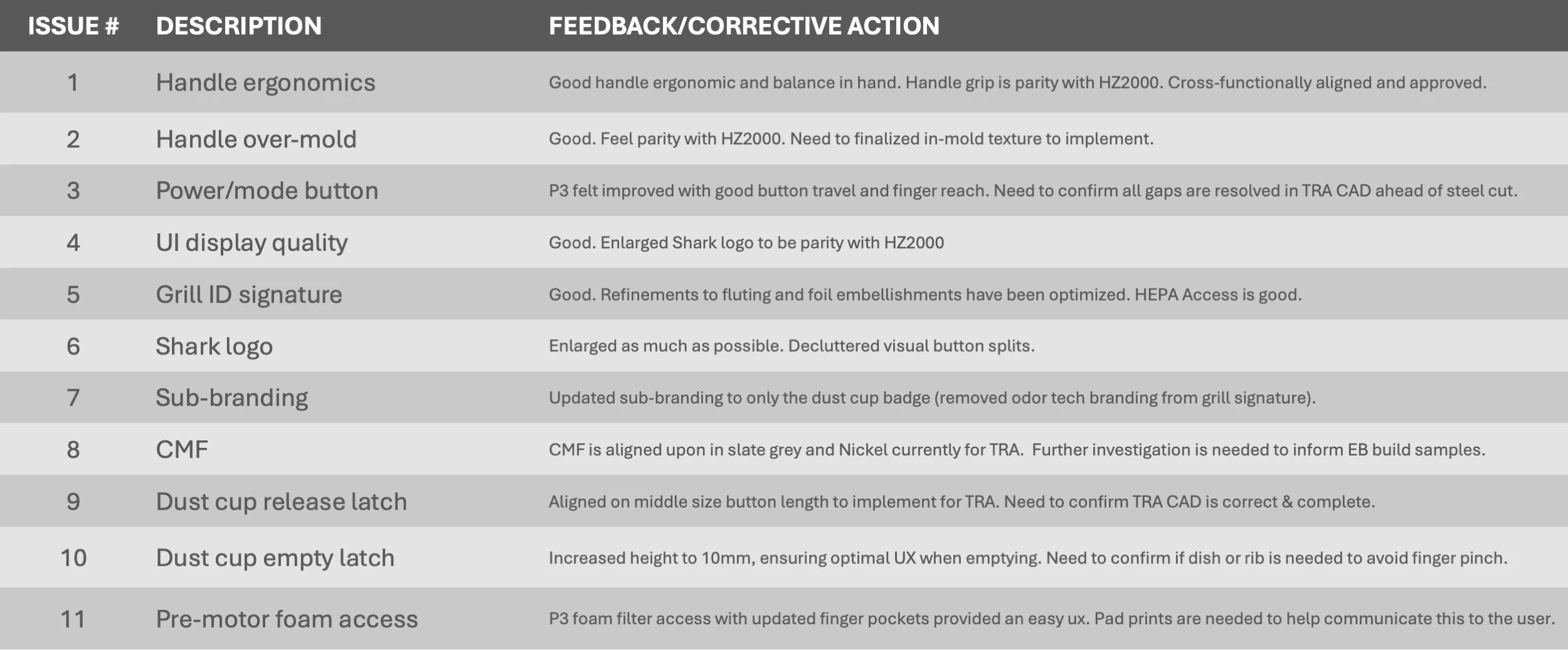

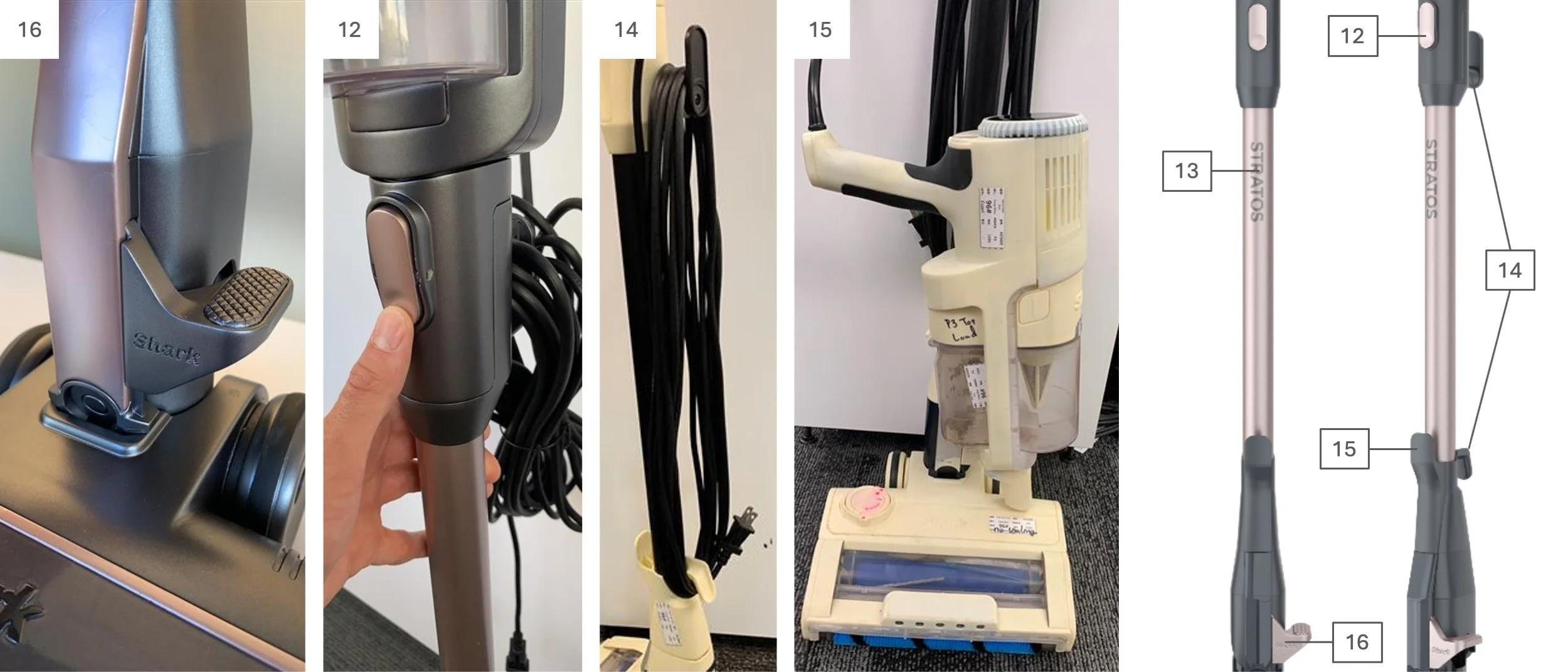

HZ3000 - TRA ID: Deep Dive

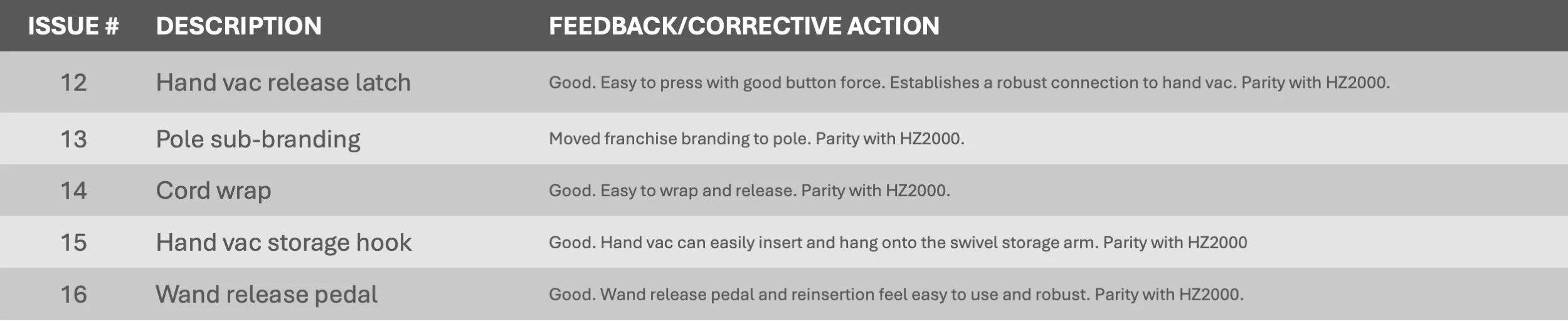

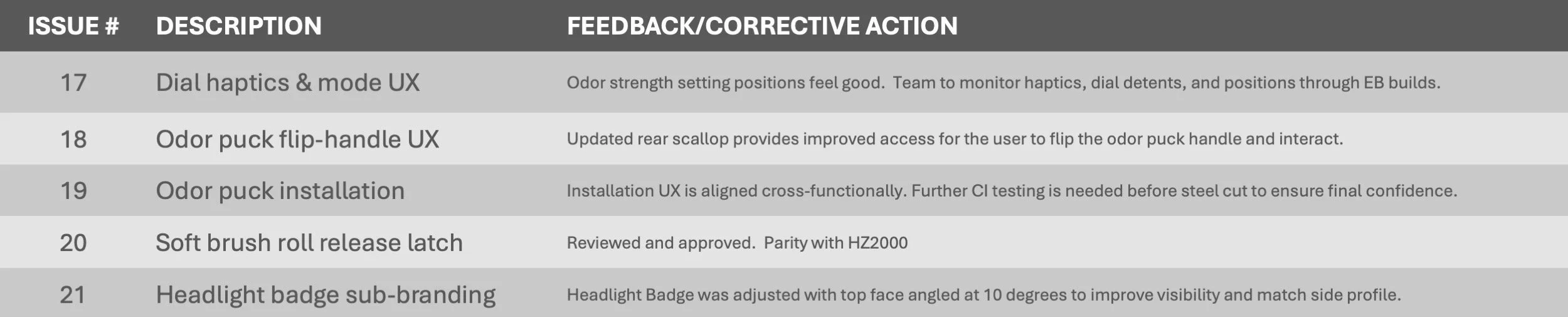

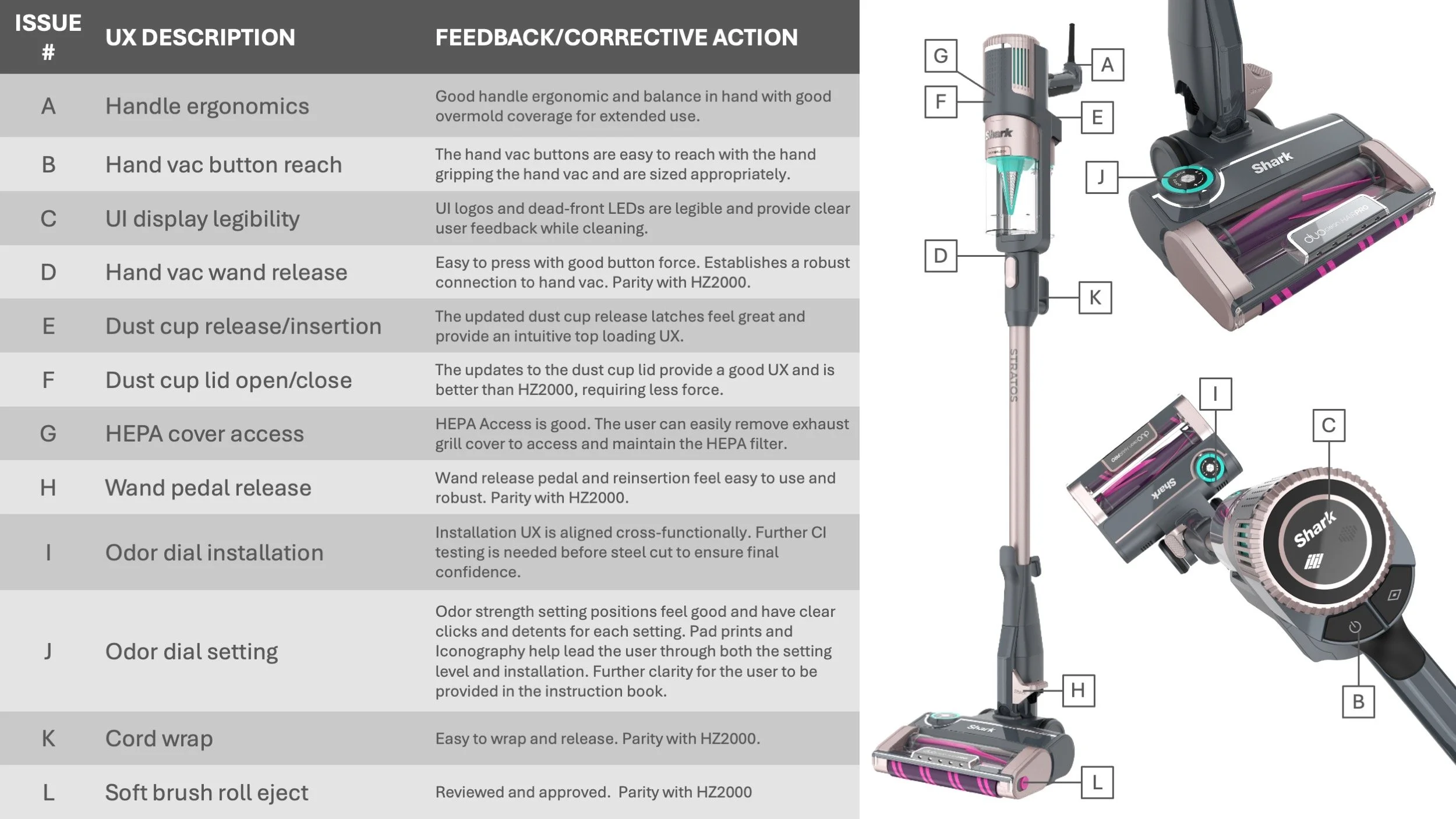

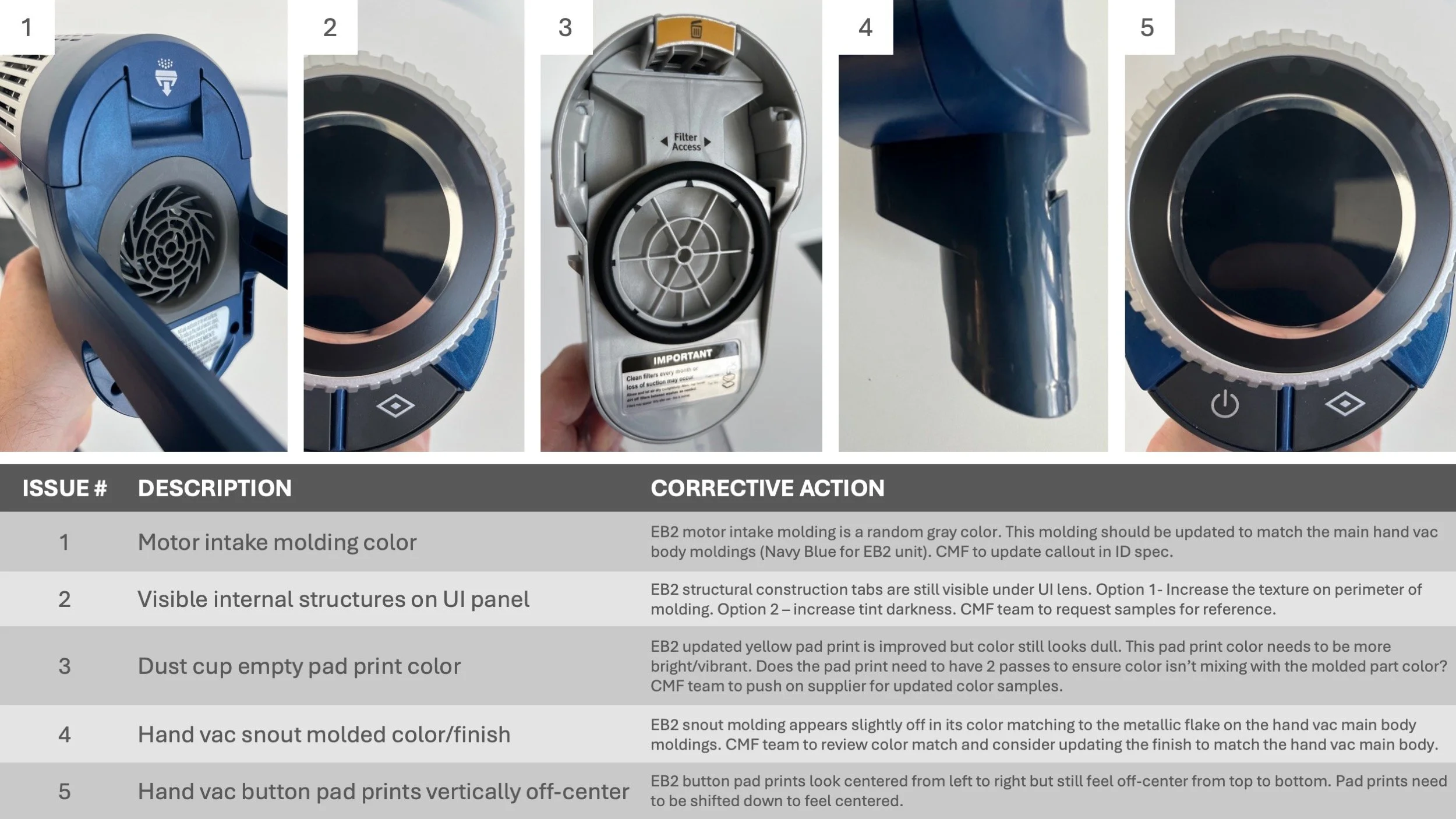

To ensure the ID is fully ready and finalized for TRA, ID takes the design through a “deep dive” where we review the latest functional samples and “golden sample” ID model. We dissect all aspects of the design, both aesthetically and from a user-experience perspective. We confirm everything that is working and identify any last areas in need of improvement or refinement.